Sect07_CSMG_b.fm

7-2

04/26/2019

Steam Master Instruction Manual

7.2

Feedwater Pump Maintenance

Avoid bodily injury. Always lock-out main

electrical power to the machine to prevent

accidental machine startup when repairing or

performing maintenance on the machine.

7.2.1

Check-Valve Maintenance

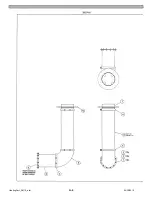

(See Fig. 7-3.)

a. Unscrew check-valve caps (3) from

check-valve housings and disassemble

discs (6) and springs (2 and 5) from caps.

Remove scale and pits from discs by rub-

bing them in a “figure 8” motion on a

piece of fine sandpaper (wet-or-dry no.

400 or finer) placed on plate glass. Discs

must be perfectly smooth and flat for

proper water pump operation.

Remove and process check-valves one

at a time to avoid interchanging parts.

b. Inspect springs (2 and 5) for distortion and

for free length. Free length of discharge

springs (5) should be 3/4 inch; free length

of intake springs (2) should be 1/2 inch.

Replace broken or distorted springs.

c. Damaged seats (1) may be removed with a

screw extractor (E-Z Out). Turn extractor

while lifting firmly until seat is removed.

Drive replacement seats in place with a

special seat driving tool (part no. UH-

18389) to avoid damage to the seat face.

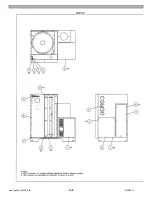

7.2.2

Replacing Check-Valve Seats

To replace valve seats, use a special seat

puller (Part No. UH-25257) and a special seat driver

(Part No. UH-18389). A screw extractor (E-Z Out)

may also be used when removing seats. Proceed as

follows:

a. Adjust puller stem counterclockwise until

retracted catch extends below valve seat

when puller is inserted into check-valve

housing (Inset A, Fig. 7-4).

b. Extend catch and turn stem clockwise in

body until catch meets the bottom of the

valve seat (Inset B, Fig. 7-4)

Fig. 7-3.

Pump Check-valve Maintenance

1. Check-valve Seat

2. Intake Spring

3. Check-valve Cap

4. Gasket

5. Discharge Spring

6. Check-valve Disc

PUMP ASSEMBLY

INTAKE/DISCHARGE

CHECK-VALVE

FEEDWATER

DISCHARGE

CHECK-VALVE

Summary of Contents for Steam Master CSMG-15

Page 1: ...STEAM MASTER SERIES USER MANUAL Cover CSMG 15 30 40 R027880B 20190603 ...

Page 8: ...vi The controls and features may differ depending on the unit s size and specifications ...

Page 9: ...vii The controls and features may differ depending on the unit s size and specifications ...

Page 14: ...Specifications_CSM_a fm xii 11 22 2018 This page intentionally left blank ...

Page 44: ...Sect05_CSMG_a fm 5 6 11 26 2018 Steam Master Instruction Manual NOTES ...

Page 68: ...HeatingSect_SM15_a fm A 2 04 30 2019 Fig 01A Main Heating Section SM15 ...

Page 69: ...04 30 2019 A 3 HeatingSect_SM15_a fm FIG 01A Main Heating Section SM15 ...

Page 70: ...HeatingSect_SM15_a fm A 4 04 30 2019 Fig 01B Economizer Stack Outlet Kit SM15 ...

Page 71: ...04 30 2019 A 5 HeatingSect_SM15_a fm FIG 01B Economizer Stack Outlet Kit SM15 ...

Page 72: ...HeatingSect_SM30_b fm A 6 12 05 2018 Fig 01C Main Heating Section SM30 ...

Page 73: ...12 05 2018 A 7 HeatingSect_SM30_b fm FIG 01C Main Heating Section SM30 ...

Page 74: ...HeatingSect_SM30_b fm A 8 12 05 2018 Fig 01D Economizer Coil SM30 ...

Page 75: ...12 05 2018 A 9 HeatingSect_SM30_b fm FIG 01D Economizer Coil SM30 ...

Page 76: ...HeatingSect_SM45_b fm A 10 04 30 2019 Fig 01C Main Heating Section SM40 ...

Page 77: ...04 30 2019 A 11 HeatingSect_SM45_b fm FIG 01C Main Heating Section SM40 ...

Page 78: ...HeatingSect_SM45_b fm A 12 04 30 2019 Fig 01D Economizer Coil SM40 Sht 1 of 2 ...

Page 79: ...04 30 2019 A 13 HeatingSect_SM45_b fm FIG 01D Economizer Coil SM40 ...

Page 86: ...Sep Trap PressMfld_SM153040_b fm A 20 04 30 2019 Fig 02E Pressure Indicating System ...

Page 87: ...04 30 2019 A 21 Sep Trap PressMfld_SM153040_b fm FIG 02E Pressure Indicating System ...

Page 90: ...PumpHkup C1 C2_parts_a fm A 24 03 05 2019 Fig 05A Pump Assy C1 ...

Page 91: ...03 05 2019 A 25 PumpHkup C1 C2_parts_a fm FIG 05A Pump Assy C1 ...

Page 92: ...03 05 2019 A 26 PumpHkup C1 C2_parts_a fm Fig 05B Pump Assy C2 ...

Page 93: ...PumpHkup C1 C2_parts_a fm A 27 03 05 2019 FIG 05B Pump Assy C2 ...

Page 98: ...Blank_Left fm A 32 08 16 2017 This page intentionally left blank ...

Page 106: ...R027906A 2018 10 22 ...

Page 107: ...NOTES ...

Page 108: ...Steam Generator Instruction Manual This page intentionally left blank ...

Page 109: ......