Repair or Warranty Contact

Clayton Associates, Inc. • 1650 Oak Street • Lakewood, New Jersey 08701 • P.+1-732-363-2100 F.+1-732-364-6084

TV-1400

Page 12

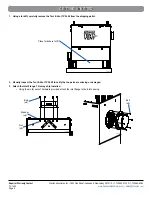

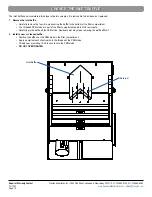

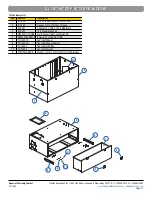

5. Attach the compressed air line.

• Verify the TV-1400 compressed air valve is in the

OFF

position.

• Connect the compressed air line to a compressed air source.

• Connect the compressed air line coupler to the compressed air plug on the TV-1400.

• Compressed air must be clean, dry, and oil free to prevent blockage of the pneumatic system.

• Compressed airline and fittings must have a minimum diameter of 1/2 inch.

• Compressed air supply must provide at least 90 psi.

• Compressed air supply must provide a minimum of 50 cfm.

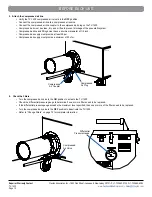

6. Check the Filters.

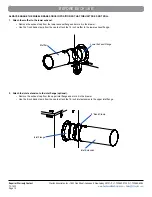

• Turn the compressed air valve to the

ON

position to activate the TV-1400.

• Check the differential pressure gauge to determine if one or more filters need to be replaced.

• If the differential pressure gauge exceeds the maximum level specified, then one or more of the filters need to be replaced.

• Turn the compressed air valve to the

OFF

position to deactivate the TV-1400.

• Refer to “Change Filters” on page 15 for complete information.

BEFORE EACH USE

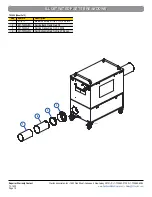

TV-1400_030

Compressed

Air Coupler

Compressed

Air Plug

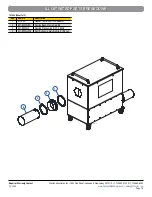

TV-1400_031

Compressed

Air Valve

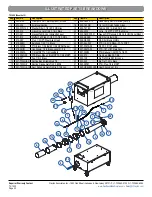

TV-1400_032

Differential

Pressure Gauge