Copyright © 2016 Clayton Associates, Inc. • 1650 Oak St. • Lakewood, NJ 08701

800-248-8650 • www.VacuumSanding.com

5

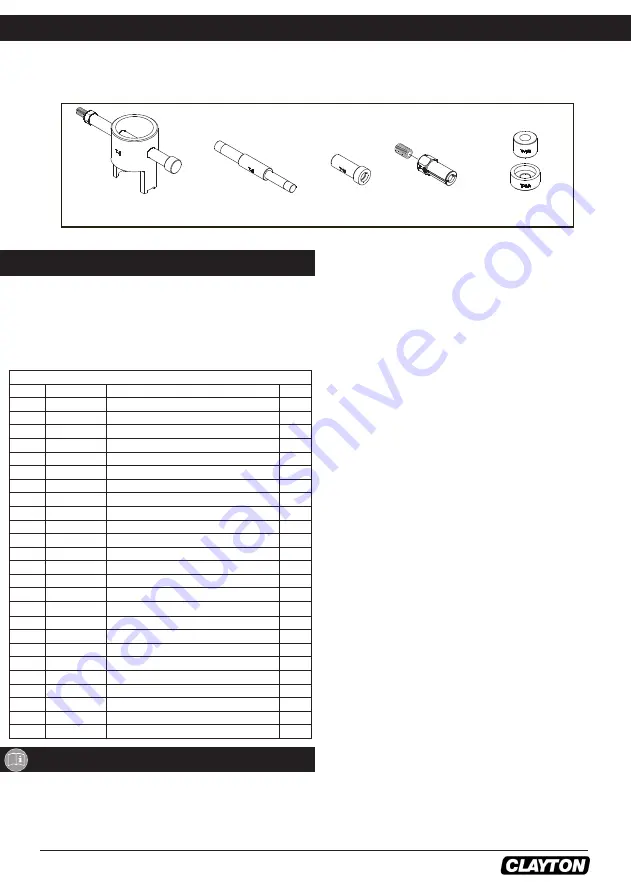

Clayton Service Tools and Accessories

When a Clayton ROS needs to be serviced, we offer a tool kit to make the disassembly/assembly fast and easy. The Service

Tools are highly recommended for use with the Overhaul Service Kit. NOTICE: To receive any expressed or implied warranty,

the tool must be repaired by an authorized Clayton Service Center. The 5 in. and 6 in. TwoHAND™ Random Orbital Sanders

Service Instructions section provided are for use after completion of the warranty period.

UNIVERSAL SERVICE TOOL KIT

T-6 MOTOR LOCK RING

WRENCH/SPINDLE PULLER

T-8 MOTOR FACE PLATE

BEARING REMOVAL TOOL

T-13 BEARING

PRESS TOOL

T-9 12 mm ID

BEARING PULLER

T-1 ROS SPINDLE

BEARING PRESS TOOLS

DISASSEMBLY INSTRUCTIONS

Motor Disassembly:

To prevent damage to the motor assembly the following

sequence must be followed:

1. Remove the Pad with the 24 mm Pad Wrench.

2. Unscrew the Lock Ring with the T-6 Motor Lock Ring

Wrench/Spindle Puller Tool. The motor assembly and

Lock Ring can now be lifted out of the Motor Housing.

3. Remove the Retaining Ring and the O-Ring from the

Cylinder.

4. Remove the Rear Endplate. This requires supporting

the Rear Endplate using a Bearing Separator and light

-

ly pressing the shaft through the Bearing and the Rear

Endplate. Remove the Cylinder and the five Vanes and

Rotor from the shaft of the Shaft Balancer. Remove the

Keys then press off the Front Endplate (with Bearing),

O-Ring and the Lock Ring. It may be necessary to

remove the Bearing with a Bearing Separator if it came

out of the Front Endplate and stuck to the shaft of the

Shaft Balancer.

5. Remove and discard Dust Shield from the Shaft Bal

-

ancer.

6. Remove the bearing(s) from the endplates by using the

T-8 Bearing Removal Tool to press out the bearings.

Shaft Balancer and Spindle Disassembly:

1. With a thin screwdriver pick out the slotted end of the

Retaining Ring and peel out.

2. Screw the threaded end of the T-6 Motor Lock Ring

Wrench/Spindle Puller Tool into the Spindle until hand

tight. Apply a gentle heat from a propane torch or hot

air gun to the large end of the Shaft Balancer until it is

about 212° F (100° C) to soften the adhesive. Do not

over heat. Remove the spindle assembly by using the

slider to pull the spindle assembly outward. Allow the

parts to cool until they are safe to handle. Do not “bang

out” the spindle assembly using the T-6 Motor Lock

Ring Wrench/Spindle Puller Tool because this could

damage the Bearing.

3. The AirSHIELD™ components are held in place by

the light press fit of the Retainer. These components

can be damaged during removal and may need to be

replaced if removed. To remove the Retainer, use an

NOTICE: To receive any expressed or implied warranty, the

tool must be repaired by an authorized Service Center.

The 5 in (127 mm.) and 6 in. (150 mm) TwoHAND™ Ran

-

dom Orbital Sander Service Instructions section provided is

for use after completion of the warranty period.

Service Instructions

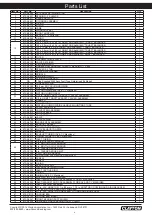

PN 673-B0537 Clayton General Rebuild Kit Contents

Item

Part No.

Description

Qty.

1

673-A0040 External Retaining Ring

1

17

673-A0090

Retaining Ring

1

2

673-A0021 Bearing – 2 Shields

1

59

673-A0628

O-Ring

1

5

673-A0042

O-Ring

1

54

673-A0043

O-Ring

1

14

673-A0122

Filter

1

15

673-A0121 Check Valve

1

16

673-A0120 Valve Retainer

1

41

673-A0500 Exhaust Gasket

1

35

673-A0655 Valve Stem Assembly

1

40

673-A0730 Airline Seal Assembly

1

6

673-B0118

Rotor

1

7

673-A0445 Vanes

5

8

673-A0041

Key

2

10

673-A0019

Bearing

1

18

673-A0751

Bearing

1

19

673-A1767

Spacer

1

56

673-A0039

Internal Retaining Ring

1

60

673-A0776 Muffler

2

27

673-A0032 Muffler Insert

1

37

673-A0009 Valve Seat

1

38

673-A0007 Valve

1

39

673-F0094 Valve Spring

1

N/A 673-A2152 5/6 in. TwoHand ROS Instructions

1

Clayton

™

General Rebuild Kit

The Clayton General Rebuild Kit PN 673-B0537 contains

all the replacement parts that naturally wear over time

and a straightforward manual to make servicing a Clayton

sander simple. Overhauling the Random Orbital Sander

can be made even easier with the use of the above Service

Tools. The Service Tools also reduce the chance of im

-

proper assembly.