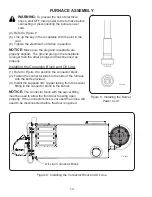

Installing the Combustion Chamber Target:

NOTICE:

Damage to the combustion chamber may occur if the furnace is used with a

damaged or missing target. Inspect the target regularly for proper positioning and wear.

(1) Refer to Figure 6 to view the proper position of the combustion chamber target.

(2) Open the front door of the furnace by loosening the two over-center latches and swinging

the door open.

(3) Guide the target toward the back of the combustion chamber. Hang the loop on the back

of the target on the hook welded to the back of the combustion chamber.

(4) Close the front door and secure the two over center-latches.

13

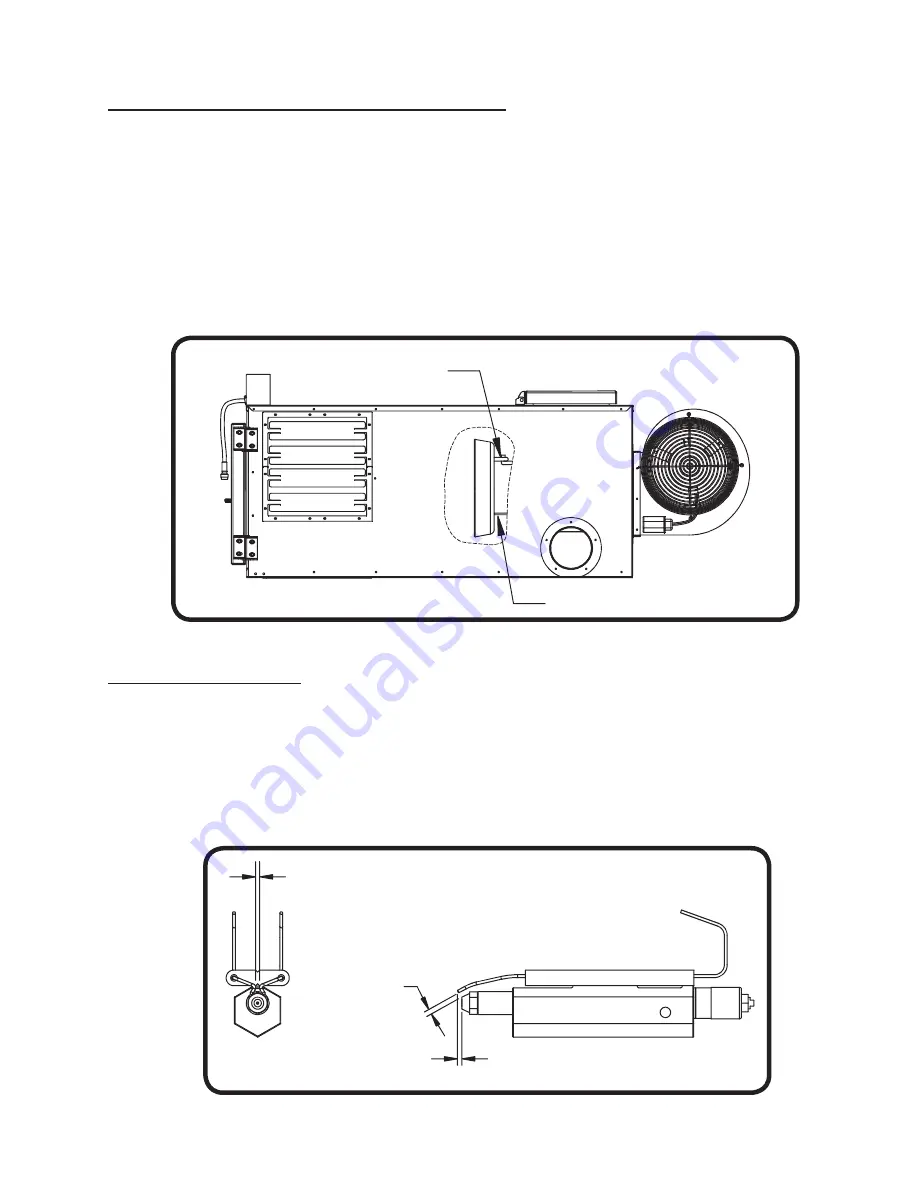

Installing the Burner:

Figure 6: Proper Position of the Combustion Chamber Target

NOTICE:

The nozzle, electrode, and retention head may need adjustment after shipping and

installation. The nozzle should remain centered in the retention head. Refer to Figure 7 for

proper dimensions.

(1) Remove the two serrated flange nuts from the front door.

(2) Slide the blast tube of the burner through the throat of the front door.

(3) Fasten the burner to the front door by tightening the two serrated flange nuts.

Figure 7: Nozzle and Electrode Settings

FURNACE ASSEMBLY

3/16" GAP

BETWEEN

ELECTRODES

AND NOZZLE

CE70018

1/8" GAP BETWEEN

ELECTRODES

ELECTRODE 1/8"

PAST NOZZLE

CE70020

Target hanging on back of

combustion chamber hook and

resting against stabilizer

Target Stabilizer

Summary of Contents for CE-140

Page 50: ...50 NOZZLE ADAPTER HEATER BLOCK ASSEMBLY 2 3 19 5 7 8 15 9 17 14 18 16 13 1 4 6 10 11 12 ...

Page 52: ...52 MANIFOLD BLOCK ASSEMBLY 8 6 2 1 4 17 3 9 5 7 12 13 14 15 16 18 19 11 10 ...

Page 58: ...58 3 4 6 1 2 5 CE 140 180 BLOWER ...

Page 62: ...62 2 3 4 5 6 1 CE 250 BLOWER ...

Page 66: ...66 CE 330 BLOWER 12 8 7 4 13 1 2 3 5 6 9 10 11 ...

Page 70: ...70 CE 440 BLOWER 12 8 7 4 13 1 2 3 5 6 9 10 11 ...