BLX-100W Manual Page 5 of 9

Updated: 02/11/21

USER MANUAL: BLX-100W

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Gener

al

Ins

talla

tion

Oper

ation

Appendix

Installation (continued)

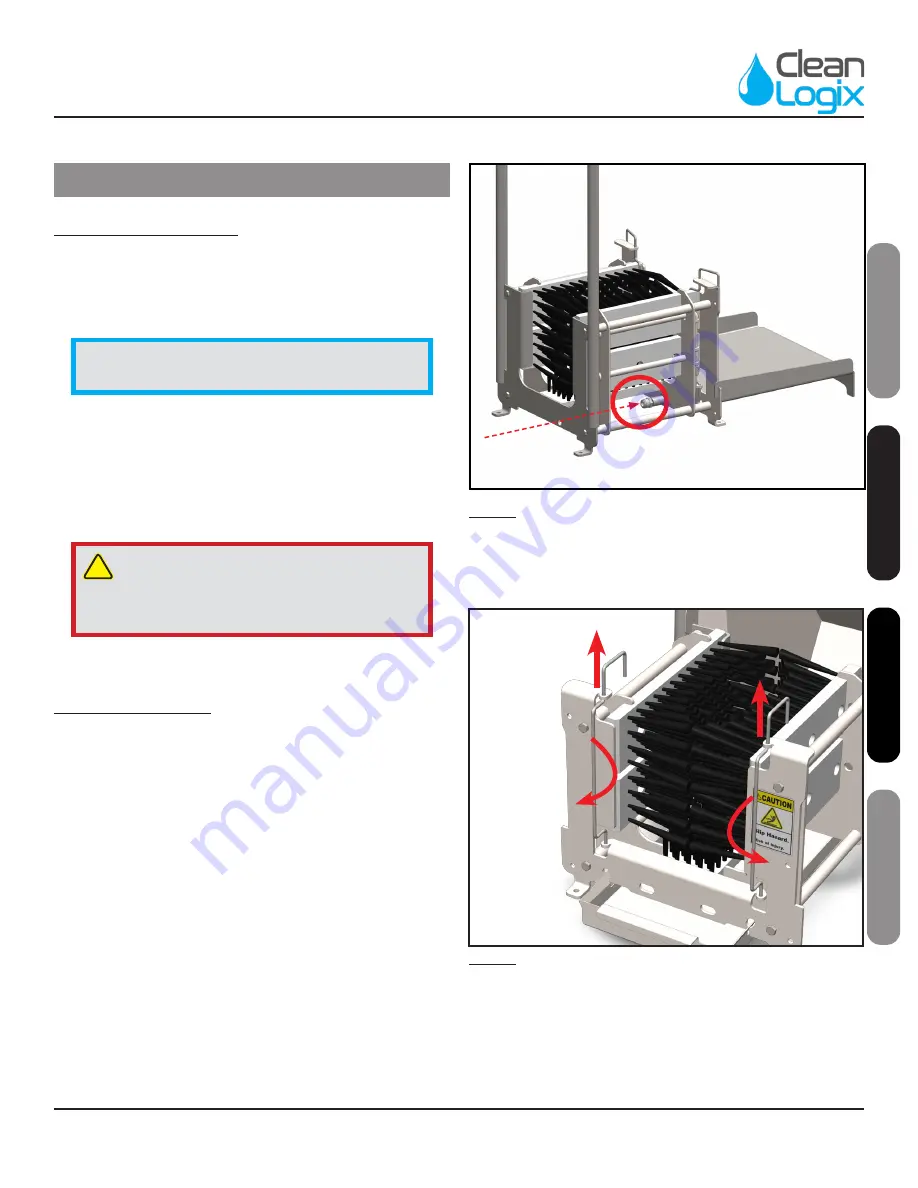

Fig. 5.1:Water line of BLX-100W

Fig. 5.2:

Brush clip rotation for brush removal

Removing Brushes

The brushes are held in place by the brush clip at the

front of the unit.

1. To remove the brushes, pull up on the clip and

twist them outward, as shown in [Figure 5.2].

2. Once unlocked, the brushes can be removed for

cleaning, by slipping them out from their holders.

Plumbing (continued)

3.

Using the push to connect fitting, connect the

Venturi system to the BLX's water line located

under the unit, near the foot plate [Figure 5.1]

4.

Test the system by stepping on the footplate to

engage the unit and begin spraying.

5.

Adjust the solution output as necessary using the

included metering tips (instructions included).

NOTE:

Injector must be mounted within 10 ft.

of boot scrubber.

!

WARNING:

DO NOT use flammable liquids (i.e. alcohol

based solutions or similar) without dilution.