42

OPERATIONS MANUAL

43

RHINO-MAT

Water Pressure

(psi)

Operating Range -

Gallons Per Minute

10

2.00 - 6.40

20

2.30 - 7.50

40

2.90 - 9.50

60

3.40 - 11.00

100

4.20 - 14.00

200

5.70 - 19.00

400

7.90 - 26.00

500

8.90 - 29.00

* 700

11.00 - 35.00

* 1000

13.00 - 41.00

* 1500

16.00 - 50.00

* 2000

18.00 - 58.00

* 3000

20.00 - 70.00

* SPECIFY – S Stainless Steel Knob – Part No.

24-32S or Part No. 24-32ST (for tips) for pressure

exceeding 700 PSI.

TABLE 1

Fluid Viscosity

(cps)

Maximum Injection

(Oz/Min)

1

40

75

8

200

4

TABLE 2

Model

Pipe Size

204 B

1/2 NPT

TABLE 4

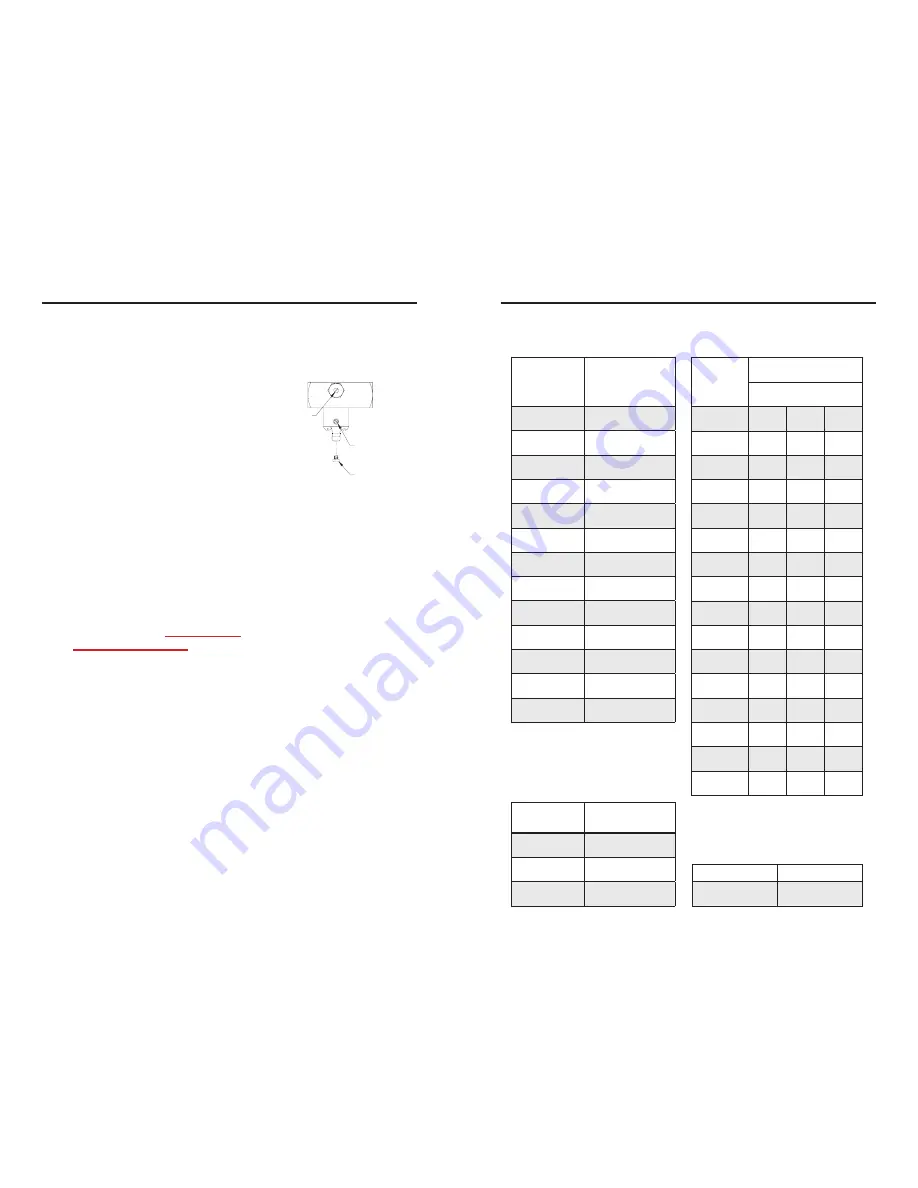

WATER BY-PASS SCREW

FIGURE 1

FINE METERING

(AS REQD.)

ADJUSTMENT

SCREW

METERING TIP

1. PARTS

A. Injector

B. Ceramic Weight.

C. Plastic tubing 8’ long with foot strainer.

2. INSTALLATION

The injector may be installed in any position in the water line with the

arrow in the direction of flow. Drop end of plastic tubing with strainer into

fluid product container. Cut tubing to convenient length, and slip open end

over injector fitting.

3. OPERATION

Warning: Use care when handling hazardous chemicals.

Note: The injector will not operate if the input water temperature

exceeds 160 degrees F.

See Fig. 1 for location of water bypass screw and fine metering

adjustment screw. Turn on water supply valve. The injector may draw

momentarily as the system is filling but normally will stop as the system

builds up to full pressure. To actuate injector, turn the bypass screw

clockwise until product begins to be drawn from the container. After the

fluid reaches the injector, the feed rate may be adjusted to the desired rate

by turning the bypass screw. The maximum injection rates are shown in

Table 2. For low injection rates, it is advisable to set the bypass screw for

more injection than required; then turn the fine metering screw clockwise

to reduce injection to the desired rate. Table 1 shows the operation range

of the injector. If the injector will not draw with the bypass screw full in,

then the water flow is below the range of the injector. If the injector draws

with the screw full out but pressure loss is excessive, then flow is above

the range of the injector. Table 3 shows the injection rates for model

204 BT using metering tips at various viscosities. Table 4 shows the

appropriate pipe size used for each injector.

DEMA ADJUSTABLE SINGLE

STAGE INJECTOR

INSTALLATION INSTRUCTIONS

Metering

Tip Color

Injection Rates (Oz/Min)

Viscosity (cps)

1

75

200

Tan

1.1

0.8

0.5

Orange

1.4

0.9

0.6

Turquoise

1.9

1.2

0.9

Pink

2.6

1.7

1.3

Clear

3.4

2.4

1.6

Brown

4.0

2.4

1.9

Red

4.9

2.9

2.2

White

6.0

3.4

2.4

Green

6.8

3.8

2.5

Blue

8.4

4.3

3.1

Yellow

13.1

5.2

3.4

Black

18.2

6.1

3.5

Purple

27.5

6.8

3.5

Gray

32.9

7.0

3.5

No Tip

39.8

7.9

3.7

All induction rates are based on a water inlet

pressure of 40 psi and operating at a full vacuum.

TABLE 3