Installer's Manual: Clean Burn Air Compressors

4-1

SECTION 4: OPERATING & MAINTAINING

THE AIR COMPRESSOR

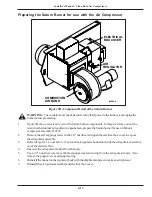

Adjusting the Air Compressor During Operation

It is very important to adjust the pressure relief on the air

compressor to provide the burner with the precise air

pressure (12 to 18 psi) required for proper burner opera-

tion. Excess air pressure is bled off through the pressure

relief.

ATTENTION:

DO NOT run the air compressor with the

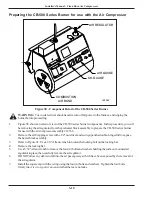

air regulator installed (see section 3 - Preparing the Burner

For Operation With the Air Compressor). This may cause

the compressor to overheat and severely damage the teflon

rings and teflon skirt in the air compressor, resulting in poor

air pressure output from the compressor.

1.

Refer to your heating equipment's

Operator's

Manual, Section 6 "Burner Start Up and

Adjustment".

Note the proper air pressure

setting. (e.g. CB-2500 furnace requires an air

pressure setting of 12 - 18 psi.)

2.

Follow the directions in Section 6 of your heating

equipment'sOperator's Manual to start the burner.

3.

Loosen the locking nut and slowly back out the

adjustment on the pressure relief valve on the air

compressor to supply proper air pressure to the

burner.

NOTE: The air gauge on the burner may

"bounce" slightly when compressed air is being

supplied by a piston air compressor.

4.

Firmly tighten the lock-down nut on the

pressure relief.

5.

Be sure to install the sound dampening assembly

over the pressure relief. This will "muffle" the

sound of the air pressure escaping through the

pressure relief.

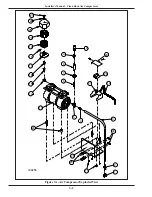

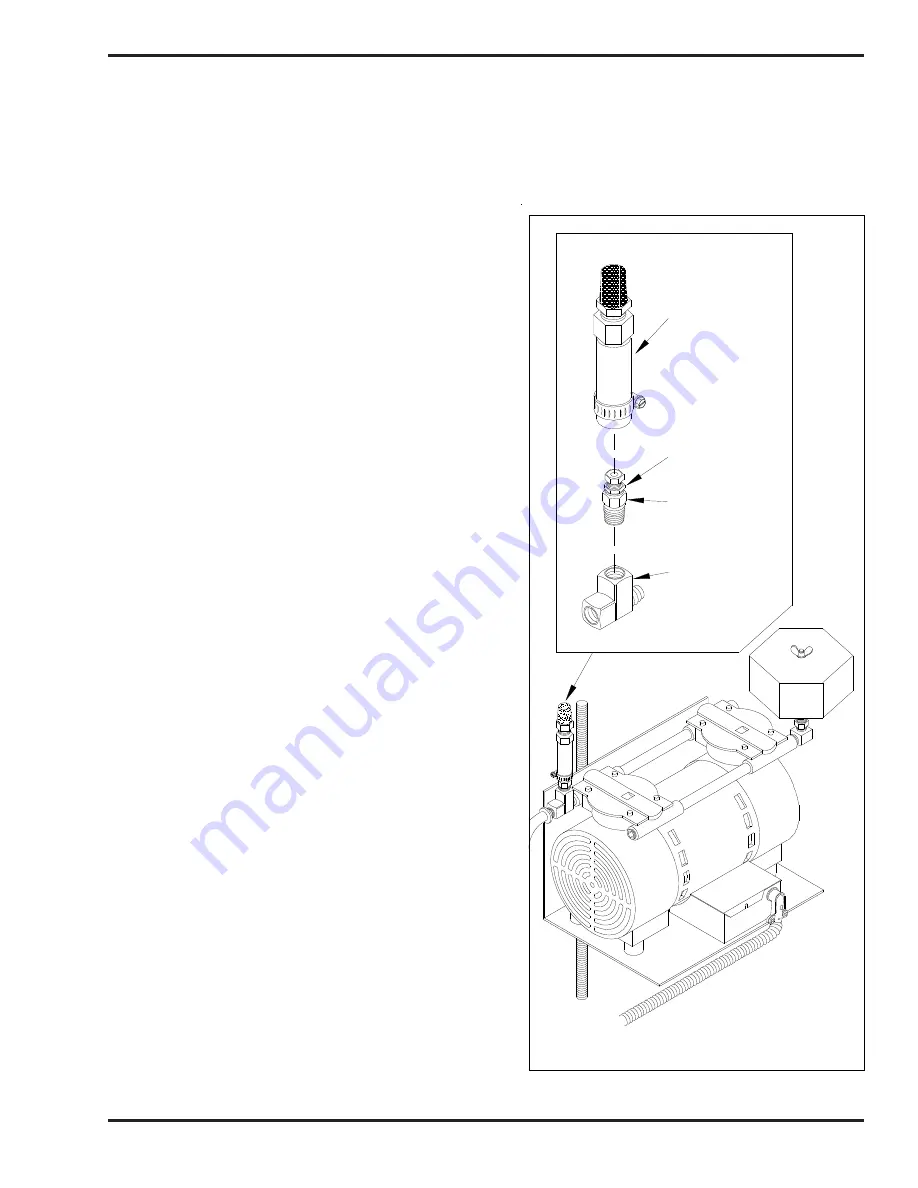

Figure 4A - Pressure Relief Valve Assembly

COMPRESSOR

OUTLET

TEE IN

RELEIF VALVE

PRESSURE

ASSEMBLY

DAMPING

SOUND

I89059

LOCKING NUT

Summary of Contents for 14336

Page 2: ......

Page 6: ......

Page 8: ......

Page 12: ...Installer s Manual Clean Burn Air Compressors 2 2...

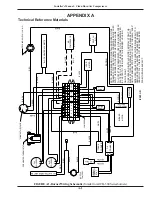

Page 32: ...Installer s Manual Clean Burn Air Compressors A 4...