SPECIAL BULLETIN

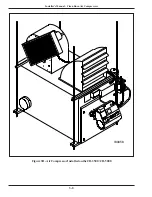

Clean Burn Model #14336 is a double-piston air compressor which can be installed on ALL Clean

Burn furnace and boiler models.

IMPORTANT INFORMATION CONCERNING THE SERVICE RATING

OF THE AIR COMPRESSOR

Air compressor model #14336 has a service rating of approximately 75%. This means that the air compressor

can operate continuously for approximately 45 minutes (75% of one hour), and then it must not operate for

approximately 15 minutes (25% of one hour) to allow the air compressor to "cool down." This works well for

most furnace/boiler installations where the unit will cycle on and off a few times during an hour.

CAUTION:

If the furnace/boiler will run continuously (without cycling on and off a few times

during an hour), you must use an air compressor with a tank.

(Refer to the air compressor specifications

for your furnace/boiler when purchasing an air compressor with a tank.)

DO NOT use air compressor model

#14336 if your furnace/boiler will run continuously for periods which exceed the 75% service rating.

This will overheat the air compressor and severely damage the teflon rings and teflon skirt in the air compressor,

resulting in poor air pressure output from the compressor.

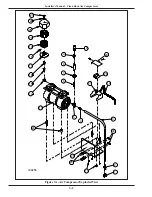

IMPORTANT INFORMATION CONCERNING ADJUSTMENT

OF THE AIR COMPRESSOR

It is very important to follow the instructions

"Adjusting the Air Compressor During Operation"

in this

manual. This procedure involves the adjustment of the pressure relief on the air compressor so that the precise

air pressure (12 to 18 psi) required for proper burner operation is provided to the burner. Excess air pressure

is bled off through the pressure relief.

CAUTION:

DO NOT run the air compressor without properly adjusting the pressure relief. This will overheat

the air compressor and severely damage the teflon rings and teflon skirt in the air compressor, resulting in poor

air pressure output from the compressor.

IMPORTANT INFORMATION CONCERNING YOUR

AIR COMPRESSOR MODEL

Summary of Contents for 14336

Page 2: ......

Page 6: ......

Page 8: ......

Page 12: ...Installer s Manual Clean Burn Air Compressors 2 2...

Page 32: ...Installer s Manual Clean Burn Air Compressors A 4...