Installation

Chimney

The chimney height and the position of the chimney terminal should conform to Building Regulations.

Check that the chimney is in good condition, dry, free from cracks and obstructions. The diameter of

the flue should not be less than 127mm and not more than 230mm. If any of these requirements are not

met, the chimney should be lined by a suitable method.

The chimney must be swept before connection to the stove.

Where the chimney is believed to have previously served an open fire installation, it is possible that the

higher flue gas temperature from the stove may loosen deposits that were previously firmly adhered,

with the consequent risk of flue blockage. It is therefore recommended that the chimney be swept a

second time within a month of regular use after installation.

If you have any doubts about the suitability of your chimney, consult your local dealer/stockist.

If there is no existing chimney then either a prefabricated block chimney in accordance with Building

Regulations Approved Document J, or a twin-walled insulated stainless steel flue to BS 4543 can be

used. These chimneys must be fitted in accordance with the manufacturer’s instructions and Building

Regulations.

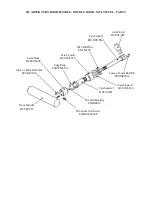

Flue Draught

A flue draught of minimum 1.2mm to a maximum 2.5mm water gauge is required for satisfactory

appliance performance. The flue draught should be checked under fire at high output. If it exceeds the

recommended maximum, a draught stabiliser must be fitted so that the rate of burning can be

controlled and to prevent over firing. If the reading is less than the recommended minimum then the

performance of the appliance will be compromised.

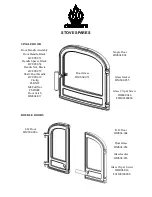

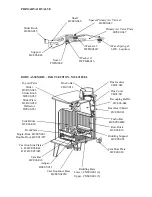

Connection to the Chimney

An existing fireplace opening can be bricked up or sealed with a register plate. A short length of flue

pipe of a minimum 127mm internal diameter may then be used to connect the stove to the chimney.

This flue pipe should be of 316 grade stainless steel or vitreous enamelled, nominal thickness 1.2mm.

Ensure that the pipe end is no closer than 76mm to the side or rear chimney walls.

Ideally, the old fireplace should be filled in so that there is a smooth streamlined entry into the flue

way.

The length of any horizontal run of flue pipe must not exceed 127mm.

It is essential that all connections between the stove and chimney-flue are sealed and made airtight.

Both the chimney and flue pipe must be accessible for cleaning and if ANY parts of the chimney

cannot be reached through the stove (with baffle brick removed), a soot door must be fitted in a

suitable position to enable this to be done.

Air Supply

The room or space containing this appliance needs no additional ventilation, unless a draught stabiliser

is fitted, in which case a permanent air opening of at least 1470mm

2

should be provided. Due

consideration should be given to air requirements for any other appliances in the same room or space.

Any air opening must be kept clear from blockage or obstruction.