9

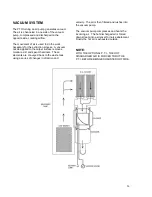

VACUUM SYSTEM

The vacuum system of the Compact is a Roots Whispair

Universal DSL 45 or 47 positive displacement rotary lobe

blower. This high performance blower provides

incredible air flow and water lift making sure carpets are

left as dry as possible. The blower is factory set for

maximum efficiency and longevity. The performance and

life of the blower greatly depends on the care and proper

maintenance it receives.

Due to the close tolerances of the internal lobes and the

housing of the blower, solid objects entering the inlet of

the blower can damage the interior.

To prevent this, Cleanco installs stainless steel filter

screens on the vacuum inlet inside the vacuum recovery

tank. This stainless steel filters should be removed daily

and cleaned. When reinstalling the filter only thread filter

on until finger tight. The lint basket should be removed

and cleaned after every job. If lint basket is not clean, it

will affect the performance of your machine.

For further information on the Roots Vacuum Blower

refer to the enclosed Roots Universal Blower Manual.

ELECTRICAL SYSTEM

The Cleanco Compact electrical system has been

specifically designed with simplicity in mind. There is one

complete wiring harness that connects all operations of

the unit. This harness is complete with specially

designed plug ends, which enable service centers easy

front panel removal if necessary. An inline fuse located

near the van battery protects the system. All wiring is

coated to protect against corrosion from moisture or

water spillage.

NOTE:

Whenever working on wiring system power side

of van battery should be disconnected for safety.

COMPACT 45 & 47 HEAT EXCHANGERS

The Cleanco Compact “MAXI HEAT” heat exchangers

are custom built by Cleanco to meet our exacting

standards for performance. The heat transfer is quick

and efficient, with no potentially damaging heat swings

or peaks. The Cleanco Compact heat exchanger is

designed with a burst rating pressure of 9000 psi, and

operating pressures up to 3000 psi. The unique dual

reverse flow exchanger system gets the most heat from

the cooling system of your van, using a reverse flow

design to maximize heat transfer delivering the highest

heat to flow ratio in the industry. The exchangers require

little maintenance other than an occasional coil flush to

remove hard water residues and scale.

COMPACT 45 & 47 PTO SYSTEM

The power take off shaft (PTO), is a precision

engineered and balanced shaft that transfers power from

the van’s engine to the Compact unit, which drives the

vacuum and high pressure pump. An outer casing with

three bearings protects the shaft. These bearings are

designed to withstand extremes of heat and friction

without breaking down. The PTO shaft has two grease

jerk fittings one at the front of the PTO shaft and one at

the rear of the PTO shaft. These two bearings require

greasing every 250 hours of operation. The

recommended grease to be used to grease the bearings

is SKF LGMT 3/0.4 bearing grease. The PTO shaft is

activated by a single switch located on the front

instrument panel. The single switch engages an electric

clutch at the front of the shaft in the engine

compartment. The shaft is firmly mounted in the engine

compartment by the front PTO mounting bracket and at

the rear of the shaft by the rear PTO mounting bracket

which is mounted to the base plate of the unit.

COMPACT FRONT INSTRUMENT PANEL

The instrument panel of the Compact puts everything at

your fingertips. Complete with vacuum gauge, hour

meter, pressure gauge, water temperature gauge and

tachometer to monitor all internal workings of the

Compact. All electrical is controlled by rocker switches,

unit power, fast idle, high pressure pump clutch, interior

lights, C.A.D. (Cleanco Auto Drain) and the accessories

switch. The BPR (Balanced Pressure Regulator) and

Chemical Flow-Meter are both located at the center of

the front panel for easy access. To the right side of the

panel is the blower lube port and the oil level sight tubes.

At the lower left side of the panel are the two high

pressure quick disconnects and the C.A.D. (Cleanco

Auto Drain). The unique design feature of the Compact

front panel, allows complete removal in approximately 90

seconds giving you complete access to the major

components.

COMPACT RECOVERY TANK

The recovery tank of the Cleanco Compact incorporates

many unique features to protect your equipment, and

save you time. The tank is made from 3/16

ths

powdered

coated marine aluminum and contains several baffles to

insure strength and durability. The recovery tank holds

100 U.S. gallons (optional 120 gallons) of soiled water

solution, giving you longer cleaning intervals between

dumping. The safety and convenience features built into

the recovery tank include a high water shut-off switch, a

built-in lint basket, sloped tank bottom, stainless steel

blower protection filters, and an inline vacuum breaker.

The high water shut-off is located at the highest point in

the recovery tank, giving you full usage of the tanks

capacity. The high water shut-off cuts the power to the

unit when the tank is full, protecting the vacuum blower

from damage. The lint basket prolongs the life of the air

filtration system, and makes draining soiled water easier

with less clogging and debris. The stainless steel blower

protection filters guard against any small debris entering

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...