10

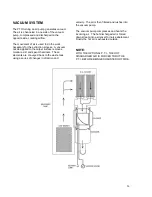

into the blower chamber which could damage the blower

itself. The inline vacuum breaker adds years to the

vacuum blowers life by reducing stress caused plugged

filters and limited air intake. The recovery tank also has

two access lids for easy access to the lint basket and the

stainless steel blower protection filters. These filters

require regular cleaning on a daily basis as a minimum.

To finish off the recovery tank Cleanco added an

integrated storage shelf, giving the operator added

space for specialty tools that may be required at the

cleaning site.

MAINTENANCE

To avoid costly repairs and downtime, it is imperative to

develop and practice good maintenance procedures.

These procedures must be preformed on a daily, weekly,

monthly, quarterly and bi annual schedule.

As part of your Cleanco package you receive a

Cleanco

Maintenance Booklet.

This booklet provides you with a

convenient format for recording the required

maintenance of your Cleanco unit and van. You are

required to perform all maintenance items in the

Maintenance Schedule and record that you have done

so in this booklet as part of your Cleanco Warranty. It is

your responsibility to keep a copy of all repair orders and

receipts that relate to your Cleanco unit and Van. These

records of services and purchases will be required to

substantiate proper maintenance to your Cleanco unit

and Van for any warranty claim.

DAILY

Check van engine oil.

Check van engine coolant level.

Check high-pressure pump oil level.

Check vacuum blower oil level.

Clean vacuum tank lint basket.

(Should be cleaned

after every job)

Clean the stainless steel blower protection filters.

Lubricate blower with

LPS/TKX

lubricant.

Winterize system if necessary.

WEEKLY

Check engine air cleaner filter. (clean as necessary)

Check Front drive belts. (adjust if necessary)

Check blower belts. (adjust if necessary)

Check high-pressure pump belt. (adjust if necessary)

Clean in-coming water filter.

Flush chemical system with 50/50 mixture of vinegar

and water.

Inspect unit for loose wires, oil leaks, and water

leaks.

Check engine RPM with unit running at fast idle.

(setting 1450 RPM under load )

Blower Speed. (actual reading)

Vacuum Gauge. (actual reading)

Temperature Gauge. (actual reading)

Hour Meter. (actual reading)

Clean wand and inspect for clogged jets.

Clean recovery tank thoroughly with high pressure

water.

MONTHLY

Change van engine oil.

Check van transmission oil level.

Check van coolant level.

Check engine air cleaner filter. (clean as necessary)

QUARTERLY SERVICE

Change oil in high-pressure pump.

Change oil in vacuum blower.

Flush entire water flow system. (coil flush if

necessary)

Check that all nuts and bolts are tight.

Check all hose clamps, tighten if necessary.

Grease front and rear PTO shaft bearings with SKF

LGMT 3/0.4 bearing grease.

BI - ANNUAL MAINTENANCE

Change the coolant and flush the

coolant system completely.

AS REQUIRED / COIL FLUSH

If your area has hard water you may see evidence of

hard water deposits form in the water system, or on the

quick connects. If scale is present, the water system

should be flushed with Coil Cleaner. This procedure may

have to be increased to a monthly interval if heavy built-

up is present. For information on flushing coils contact

your nearest Cleanco distributor.

Over all machine maintenance and appearance is very

important. It represents your company’s professional

appearance and is how you make your living. A clean

well maintained machine will give you years of reliable

performance. Maintenance, troubleshooting, and repair

is much easier on a clean well maintained unit. Regular

cleaning and maintenance will give you the opportunity

to spot any potential problems normally before they

occur.

It is important that you follow and record the

maintenance on your Cleanco unit and van according to

the Cleanco Maintenance Booklet to insure complete

warranty coverage.

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...