15

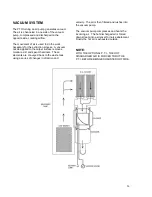

Water Pumping and Heat Transfer System:

Cold water enters the panel through the water

inlet. When the water tank is full the valve will

automatically shut off.

Water then flows from the water tank, through a

strainer, into the water pump where chemical is

introduced at this point. Then it is pumped to the

pressure regulator that provides and maintains the

desired pressure setting.

A certain amount of water is by-passed from the

pressure regulator due to over pumping capacity

of the water pump. Water that is not called for in

the cleaning process is channeled to the by-pass

coil in the recovery tank then flows to the inlet side

of the pump to be circulated again.

The heating stage occurs when the water leaving

the pressure regulator and directed to the first of

two heat exchangers. Heat from the vehicle

engine coolant is exchanged to the cleaning

solution spiraled copper tubing. This allows the

engine coolant to travel in a counter rotating

direction to the cleaning water during the

exchange process creating a very efficient transfer

of heat out of the engine and into the cleaning

solution.

The hot solution then exits the second heat

exchanger where it enters the outlet manifold.

The manifold serves as a sensing point and

connection for the high-pressure hoses.

Finally, the cleaning solution then passes through

pressure hoses and is distributed by the cleaning

tool to a surface that is being cleaned, completing

the water pumping and heating cycle of the

cleaning unit.

Optional P.T.I.

With the Optional Post Thermal Increase, the

cleaning solution goes to a second stage of

plumbing and heating which takes place in the

heater core located just after the vacuum pump.

This is the hottest point of exhaust air coming from

the vacuum pump. The hot exhaust air is forced

through the post heat core, creating the second

stage of heat transfer to the cleaning solution.

Required Maintenance of P.T.I.

Annual inspection of the fins inside the P.T.I. is a

requirement do to the potential folding over of the

fins or build up of debris, lint, dirt etc. This will

cause excessive stress on the drive line including

the blower, PTO shaft and PTO clutch. The blower

must be removed to see the possible results of the

wear and tear on the fins. Cleanco would

recommend this procedure be done by a Qualified

Service Center.

Heat Max P.T.I Operating Instructions:

Overview

The “Heat Max P.T.I.” is designed to transfer the

exhaust heat generated by the vacuum blower, to

the cleaning solution as the final heating stage. To

fully understand the heat transfer system of the

Cleanco Compact the following steps occur.

Before the P.T.I. will efficiently transfer heat to the

cleaning solution, the blower must be brought up

to temperature. This is accomplished when the

vehicle coolant system is first brought up to

operating temperature either through idling or

driving to the job site. Then the unit must be

turned on to high idle with the vacuum port of the

recovery tank closed off with the plug on the inlet

barb. The operating temperature of the P.T.I. will

be available in about ten minutes of running unit.

The P.T.I. will take much longer to reach operating

temperature if this procedure is not done and in

fact will cool the water until the blower can reach

the desired transfer heat rate.

Step 1

The water flows from the fresh water tank through

a strainer, into the water pump where it is pumped

to the pressure regulator providing constant

desired pressure.

Step 2

The next stage of water flow is to the heat

exchangers (Dual or Quad), when water is called

for in the cleaning process, it flows to the heat

exchangers under pressure. Heat from the engine

coolant is exchanged to the cleaning solution

through a series of spiraled copper tubing. This

allows the engine coolant to travel in a “reverse

flow” direction to the cleaning solution creating a

very efficient transfer of heat out of the engine and

into the cleaning solution.

Step 3

The last stage of the heat exchange takes place in

the “Heat Max P.T.I.” located under the baseplate.

This is the hottest point of the exhaust from the

vacuum blower which is forced through th

e “Heat

Max P.T.I.”. The cleaning solution travels from the

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...