21

VACUUM PUMP

Refer to the Vacuum Pump Operation and

Service Manual for specific instructions.

Lubrication:

We recommend that you use Roots

Synthetic Blower Lubricant in the vacuum pump

for all operation temperatures. This lubricant is

formulated especially for positive displacement

blower service to provide maximum blower

protection at any temperature. One filling of

Roots Synthetic oil will last many times longer

than a premium mineral oil.

NOTE: Roots Synthetic oil is the oil

which ESTEAM puts in the vacuum pump

at the factory. Topping off or adding

petroleum oil to synthetic oil is NOT

recommended.

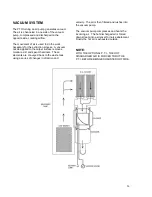

1.

Check the oil level

daily

to assure the

proper level.

PROPER LEVEL

cannot be

overemphasized. Too little oil will ruin

bearings and gears. Too much oil will cause

overheating. Use the illustration as a guide

when adding oil.

2.

To prevent rust from building up inside the

vacuum pump (if moisture exists) we have

provided a lubrication cup on the front of the

unit.

First run the unit at least

1 minute

to remove any

moisture from the vacuum pump. Next, fill the

lubrication cup with

LPS-TKX

, or a similar

lubricant, for

5 seconds

while the unit is running

and the vacuum inlets are sealed. Do this at the

end of

each working day.

3.

Drain, flush and replace oil

every 200 hours

or yearly, whichever comes first.

Change

oil more frequently if inspection so indicates.

With Roots Synthetic lubricant, perform the

oil change maintenance

every 500 hours or

once per year, whichever comes first.

4.

Vacuum pump lubrication is vital to

performance of our pump. Failure to follow

the maintenance schedule in the

“Maintenance Schedule” can lead to

permanent damage to your blower.

WATER PUMP

1.

Check the crankcase oil level

daily

to assure

the proper level. Use the illustration as a

guide when checking the oil level. If the

level has dropped, check for the source of

leakage and repair.

2.

Change the crankcase oil with Cat Pump

Crankcase Oil, after the

first 50 hours

of

operation. Drain and refill the crankcase oil

with Cat Pump Crankcase Oil

every 500

hours

thereafter.

3.

Other Cat approved oil equivalents are: Mobil

DTE 16, Amoco Rykow 68, and Shell Tellus

T68.

VACUUM INLET FILTERS

(IN WASTE TANK)

1.

The vacuum filters in the waste tank should

be removed and cleaned

daily

. If this is

done, the filters will last for a long period of

time.

VACUUM RELIEF VALVE

While the unit is running at full RPM, block the

air flow at the vacuum inlet connection and read

the vacuum gauge. If adjustment is required,

shut the unit down and adjust the vacuum relief

valve locking nut tension. Start your unit and

read the vacuum gauge. Repeat this process

until the relief valve opens

at 14” Hg on a

Compact 45 and 12

”Hg on a Compact 47.

Summary of Contents for Compact 45

Page 1: ...VERSION AUG 2017...

Page 13: ...12...

Page 14: ...13...

Page 18: ...17 WATER PUMPING AND HEAT TRANSFER SYSTEM...

Page 19: ...18 WATER PUMPING AND HEAT TRANSFER SYSTEM DUAL HEAT EXCHANGER WITH P T I OPTION...

Page 28: ...27 CLEANCO COMPACT OVERHEAD VIEW...

Page 29: ...28...

Page 30: ...29 FRONT PANEL 45 47 FRONT VIEW...

Page 31: ...30 FRONT PANEL 45 47 BACK VIEW...

Page 33: ...32 FRONT PANEL PLUMBING P 1...

Page 34: ...33 FRONT PANEL PLUMBING P 2...

Page 37: ...36 COMPACT RECOVERY TANK...

Page 39: ...38 COMPACT BASEPLATE 45 47 P 1...

Page 40: ...39 COMPACT BASEPLATE 45 47 P 2...

Page 45: ...44 KIT INSTALLATION 45 47 P 1...

Page 46: ...45 KIT INSTALLATION 45 47 P 2...

Page 49: ...48 DUAL HEAT EXCHANGER...

Page 51: ...50 P T I...

Page 53: ...52 COVER HOLDER KIT...

Page 55: ...54 PTO SHAFT...

Page 58: ...57 C A D EXTERNAL OPTION PAGE 1...

Page 59: ...58 C A D EXTERNAL OPTION PAGE 2...

Page 61: ...60 F W TANK AQUA STORAGE 120 GALLON...

Page 63: ...62 F W TANK AQUA REEL TANK 125 GAL P 1...

Page 64: ...63 F W TANK AQUA REEL TANK 125 GAL P 2...

Page 75: ...74 CLEANCO COMPACT ELECTRIC WIRING P 1...

Page 76: ...75 CLEANCO COMPACT ELECTRIC WIRING P 2...

Page 77: ...76...

Page 78: ...77...

Page 79: ...78...

Page 80: ...79...

Page 81: ...80...

Page 82: ...81...

Page 83: ...82...

Page 84: ...83...