5. Service

☞

For repairs, please contact your specialist wholesaler

or one of the service shops.

☞

You will be expertly and quickly served.

This machine is not approved for use on public paths

and roads.

6. Servicing instructions

The following instructions must always be

observed

☞

When cleaning and servicing the machine, replacing

parts or when changing over to a different function,

switch off the drive and remove the plug.

☞

The power supply lead must not be damaged by

driving over it, crushing, tugging etc.

☞

Check the power supply lead regularly for signs of

damage.

☞

The machine must not be used if the power supply

lead is not in perfect condition.

☞

When using or replacing the power supply or

equipment supply leads, use only those specified by

the manufacturer.

☞

When replacing the plug-and-socket connectors of

power supply or equipment supply leads, splash

protection and mechanical strength must be assured.

☞

When transported in elevators, the applicable User

instructions and safety regulations - note - in

particular capacity.

☞

Only the spray and cleaning agents suitable for the

machine’s purpose may be used.

☞

Never use highly flammable, combustible, toxic,

health-hazardous, corrosive or irritant substances.

☞

Repairs, including the fitting of spray agent lines and

hoses, may only be carried out by approved customer

service shops or by specialists in this field who are

familiar with all the relevant safety regulations.

7. Storage

If the machine is not to be used it should be stored in a dry

room which is always above 0° C.

Look for in storage absolutely sure: Set machine to brush

pressure release lever (6). Rubber lips must not be flattened.

8.

Environmental protection

Declaration of Conformity

We,

Cleanfix Reinigungssysteme AG

Stettenstrasse - CH-9247 Henau

declare under our sole responsibility that the product,

Autoscrubber

RA 410 E

from serial code No. 9001 and following

(name,type, serial number)

to which this declaration relates is in

conformity with the following stand- ard(s) or other

normative document(s).

Low voltage, machinery:

EN 60335-1 (ed.3); am1; am 2; EN 60335-2-72 (ed.2); am1

Emission:

EN 55014-1:00+A1:01+A2:02; CISPR 14-1:05 (ed.5)

Immunity:

EN 55014-2-97+A1:01; CISPR 14-2:97+A1:01(Cons. ed. 1.1)

EN 61000-6-2:05; IEC 61000-6-2:05 (ed.2)

EMF:

EN 50366:03+A1:06; IEC 62233:05:05 (ed.1)

Harmonics:

EN 61000-3-2:06; IEC 61000-3-2:05 (ed.3);

Voltage fluctuations:

EN 61000-3-3:95+A1:01+A2:05; IEC 61000-3-3:94

+A1:01+A2:05 (Cons. ed. 1.2)

( title and/or number and date of issue of the standard(s) )

following the provisions of Directive

2006 / 95 / EC - 2006 / 42 / EC - 2004 / 108 / EC

Cleanfix Reinigungssysteme AG

Roland Flück

The packaging material can be recycled.

Please do not throw the packaging

material into household waste; please

send it for recycling.

Old appliances contain valuable materi-

als that can be recy-cled; these should

be sent for recycling.. Batteries, oil, and

similar substances must not enter the

environment. Please dispose of your old

appliances using appropriate collection

systems.

RA 410 E - Englisch

Summary of Contents for RA 410 E

Page 1: ...RA 410 E Swiss Made Quality 04 2012 BA 410E 000 Englisch...

Page 7: ...RA 410 E Brush motor As at 07 07 15 Time 09 59...

Page 9: ...RA 410 E Chassis As at 07 07 15 Time 09 59...

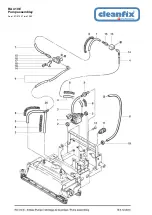

Page 11: ...RA 410 E Front suction nozzle As at 07 07 15 Time 09 59...

Page 13: ...RA 410 E Lower pushbar 1 As at 07 07 15 Time 09 59...

Page 15: ...RA 410 E Lower pushbar 2 As at 07 07 15 Time 10 00...

Page 17: ...RA 410 E Pump As at 07 07 15 Time 10 00...

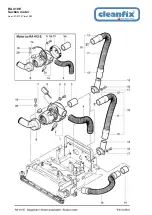

Page 19: ...RA 410 E Pump assembley As at 07 07 15 Time 10 00...

Page 21: ...RA 410 E Suction motor As at 07 07 15 Time 10 00...

Page 23: ...RA 410 E Suction nozzle As at 07 07 15 Time 10 00...

Page 25: ...RA 410 E Tank As at 07 07 15 Time 10 01...

Page 27: ...RA 410 E Wiring plan As at 07 07 15 Time 09 58...