10

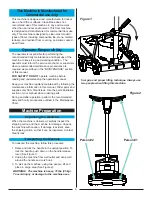

Operation

1. Unwrap the power cord and plug it into the properly

grounded outlet.

2. Pull up on the handle release lever (5). Move the

operator handle (4) downward until your arms are

almost straight. Push down on the handle release

lever (5) to lock it in place.

3. Lift up on the operator handle (4) until the driver is

flat against the floor.

WARNING! Be prepared to control the machine as

soon as the motor starts.

CAUTION! Immediately start moving the machine

back and forth. Keep the machine moving while the

motor is running to avoid damage to the floor.

4. Hold one of the operator handle grips (1) firmly, push

the switch lever safety lock (2) and the compress the

switch lever (3) to start the motor.

Note: When the switch levers (3) are released, the

machine shuts off immediately.

After Use

1. Place the operators handle (4) in the upright (vertical)

position and unplug the power cord. Wrap the power

cord around the operator hand grips (1) and the cord

hook (6).

2. Tilt the machine back and remove the pad driver from

the machine.

NEVER

store the machine with the pad

driver on the machine.

3. Wipe the entire machine with a clean, damp cloth.

4. Inspect the entire machine and all accessories for

damage. Perform any required maintenance or

repairs before storage.

5. Store the machine in a clean, dry place with the

operator handle (4) locked in the upright position.

6

3

5

2

1

Figure 7

4

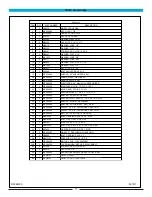

Summary of Contents for 225BUCF

Page 1: ...Floor Burnisher 225BUCF Operator s Manual...

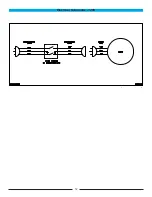

Page 12: ...12 Electrical Schematic 120V...

Page 13: ...13...

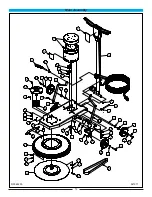

Page 16: ...16 Handle Assembly RF065300 11 29 16 1 4 2 10 3 11 9 7 8 7 6 5 18 16 14 13 14 15 17 12...

Page 19: ...19...