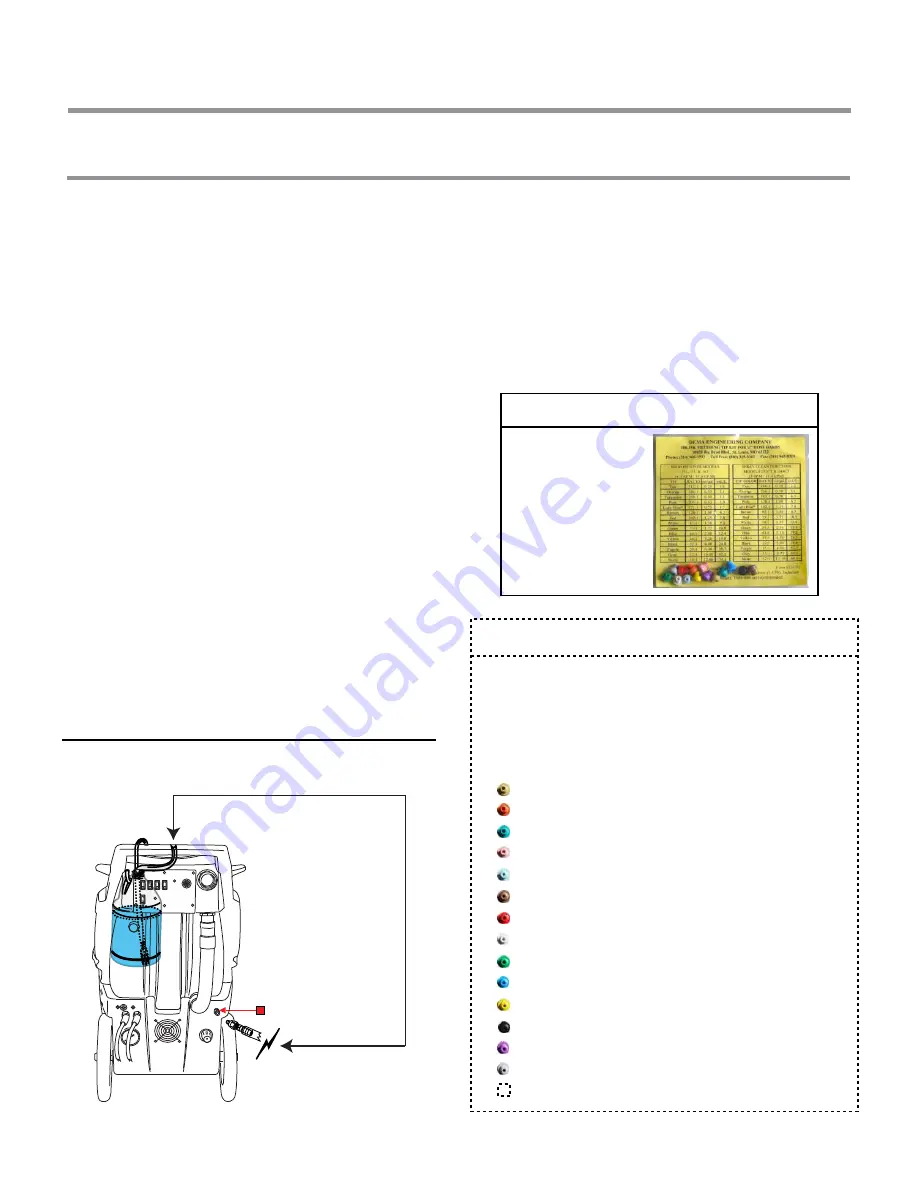

TIP

RATIO

oz/gal.

mL/L

Tan

102:1

1.25

7.8

Orange

75:1

1.70

10.5

Turquoise

60:1

2.15

13.3

Pink

43:1

3.00

18.6

Light Blue*

33:1

3.90

24.2

Brown

28:1

4.55

28.2

Red

22:1

5.80

36.0

White

18:1

7.00

43.4

Green

16:1

7.90

49.0

Blue

13:1

9.80

60.8

Yellow

9:1

14.80

91.8

Black

6:1

20.15

124.9

Purple

5:1

27.80

172.4

Gray

4.1

31.60

195.9

None

3.6:1

35.00

217.0

1 GPM/3.8 LPM

18

ABOUT:

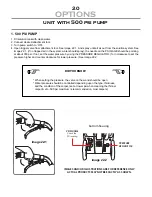

Same operation and setup as ADJUSTABLE CHEMICAL FEED SYSTEM, but preset chemical feed system do not

use chemical feed adjustable flowmeter. (See images on “ADJUSTABLE CHEMICAL FEED SYSTEM” page)

The metering tips preset chemical feed rate is controlled by a metering tip (different size) screwed into the metering

barb on the side of the unit. (see image 20.1, and the arrow)

The feed rates can be changed by using different size metering tip which is availabe with the kit.

To select a proper size metering tip for the desired dilution ratio refer to the chart. (See image 20.3)

Can be found metering system in between solution tank and the pump plumbing system.

OPTIONS

metering preset

chemical feed

system tips

TO USE:

Have a bottle or bucket of cleaning solution ready. If

you are using a cleaning chemical in powder form, mix

it with water thoroughly and make sure it is fully

dissolved. Undissolved powder can clog up the spray

jets and other parts on the unit damaging them in the

process.

A. Place the bottle or bucket of cleaning solution to

the side of the extractor. Put the end of CHEMICAL

FEED LINE all the way to the bottom of the bottle or

bucket of cleaning solution. (See image 20.2). If

CHEMICAL FEED LINE is not fully submerged in the

solution, air can get into the chemical feed and mixing

system and it may disable the system. (See images on

“CHEMICAL FEED AND MIXING SYSTEM PAGE)

B. Turn chemical feed switch on.

INJECTION RATES

2. METERING TIPS PRESET CHEMICAL

FEED SYSTEM

IMAGES AND ILLUSTRATIONS ARE FOR REFERENCE ONLY.

ACTUAL PRODUCTS MAY NOT BE EXACTLY AS SHOWN.

image 20.1

image 20.2

image 20.3

chemical feed line

chemical feed &

mixing quick

connect

Summary of Contents for CF-100 Series

Page 2: ......