SAFETY PRECAUTIONS

!!! This machine must be grounded!

Grounding provides the path of least

resistance for electrical current. To reduce

the risk of electrical shock should the

machine malfunction, the machine has a

special grounding plug. Do not remove the

ground pin under any circumstances!

This machine is intended for commercial

use. It is constructed for use in an indoor

environment and is not intended for any

other use. Use only recommended

accessories.

All operators shall read, understand and

exercise the following safety precautions:

1) Do not operate machine:

- Unless trained and authorized.

- Unless you have read and understand

operators manual.

- In flammable or explosive areas.

- With damaged cord or plug.

- If not in proper operating condition.

- In outdoor areas.

- In standing water.

- With the use of extension cords.

2) Before operating machine:

- Make sure all safety devices are in

place and operate properly.

3) When using machine:

- Only use approved burnishing pads.

- Do not run machine over cord.

- Do not pull machine by cord or plug.

- Do not pull cord around sharp

edges or corners.

- Ensure the dust collection bag is in

place and is tightly sealed to the

machine.

- Turn power switch to

“

off

“

prior to

unplugging machine.

- Do not unplug by pulling on the cord.

- Do not stretch cord.

- Do not handle plug with wet hands.

- Keep cord away from heated

surfaces.

- Do not pick up burning or smoking

debris such as cigarettes, matches

or hot ashes.

- Report machine damage or faulty

operation immediately.

4) Before leaving or servicing machine:

- Turn off machine.

- Unplug cord from outlet.

5) When servicing machine:

- Unplug cord from outlet.

- Use manufacturer supplied or

approved replacement parts.

To avoid electrical shock, please

replace the power cord

immediately if any damage is being

detected. The replacement must be

performed only by an authorized

person .

-3-

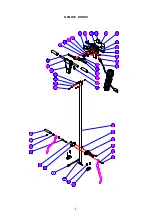

Summary of Contents for CPL-1500HS-2

Page 6: ...HANDLE GROUP 6...

Page 8: ...BASE GROUP 8...