Maintenance

(continued)

16

•

Cover Filter: Check the cover filter element mounted on the side of the air preparation system and clean as

required. Operating conditions in the equipment area will dictate the frequency required for this procedure.

Remove the filter element and clean with soap and water, drying them completely before re-installing.

Ozone Generator

•

Drive Module Operation: The Drive Module is made up of two components: the drive board and the drive

transformer. With the ozone generator cover removed, check for illumination of the drive module "Ozone Output"

LED(s) (for LED locations, see Figure 8-1); if not illuminated see Troubleshooting Guide. This procedure is to

observe

the complete operating function of the drive module(s). Before checking drive module function, remove

the ozone generator cover and depress the cover safety switch located on the ozone generator chassis (see

Appendix, Section A).

CAUTION: This overrides the cover safety switch. The ozone generator will remain

energized with the cover removed. Do not touch anything inside the ozone generator while this switch is

activated!

Please consult your ClearWater Tech dealer before attempting this procedure.

- Main Power LED: When illuminated, this “Green” LED indicates that main power is supplied to the drive

module up to the “on board” fuse of the drive board.

- Transformer Power LED: When illuminated, this “Green” LED indicates that 48V Buss power is available to

the drive module transformer (XFMR) from the “on board” fuse of the to the drive transformer.

- Ozone Output LED: The “Amber” ozone output LED will illuminate when ozone drive is being generated.

The LED will also pulse as the output increases or decreases with either the Manual Ozone Output Control

located on the bottom of the ozone generator (see Appendix, Section A), or from a Remote 4-20mA signal (see

“Installation Procedures – Electrical”).

- Fault LED: When illuminated, this “Red” LED indicates that there is a fault with the drive module or the

Ozone Reaction Chamber. If this LED is illuminated, refer to the Troubleshooting Guide.

Notes: If the drive

module goes to a fault condition, the drive board will restart every 30 seconds. If the fault is not

remedied the drive module will continue to go into a fault mode. When the drive module is in fault mode

ozone will not be generated. Before proceeding further, release the cover safety switch and replace the

ozone generator cover.

•

Cooling Fan Operation: Check to make sure the two cooling fans (mounted on the bottom panel of the ozone

generator cabinet) are operating. If not, refer to the Troubleshooting Guide.

•

Cooling Fan Filters: Check the cooling fan filter elements mounted on the bottom of the ozone generator (see

Appendix, Section A) and clean as required. Operating conditions in the equipment area will dictate the frequency

required for this procedure. Remove the filter element and clean with soap and water, drying them completely

before re-installing (see Figure 8-2).

Booster Pump(s)

•

Strainer Baskets: Check and clean the strainer basket in the booster pump(s) as required (if so equipped)

Drive Module High Output (H.O.)

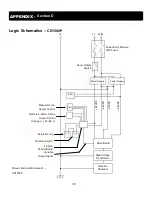

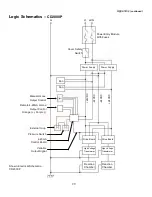

Figure 8-1

Transformers – XFMR (under

boards)

Drive Board

Ozone Output LED

Fuse

Transformer – XFMR LED

Drive Board Main Power LED

Fault LED

24VDC Output Connector

Variable Input Connector

DC Power Input Connector