11 Pentz EF5 Installation Guide

© Clear Vue Cyclones 2018

Attaching the Impeller

Improper installation of your impeller can lead to the impeller coming off during

operation. Significant damage to your system and/or bodily harm can result. It

is imperative that you read and follow these directions closely. Detailed

assembly videos can be found under the Education Center/Assembly

Instruction section of our website at www.clearvuecyclones.com.

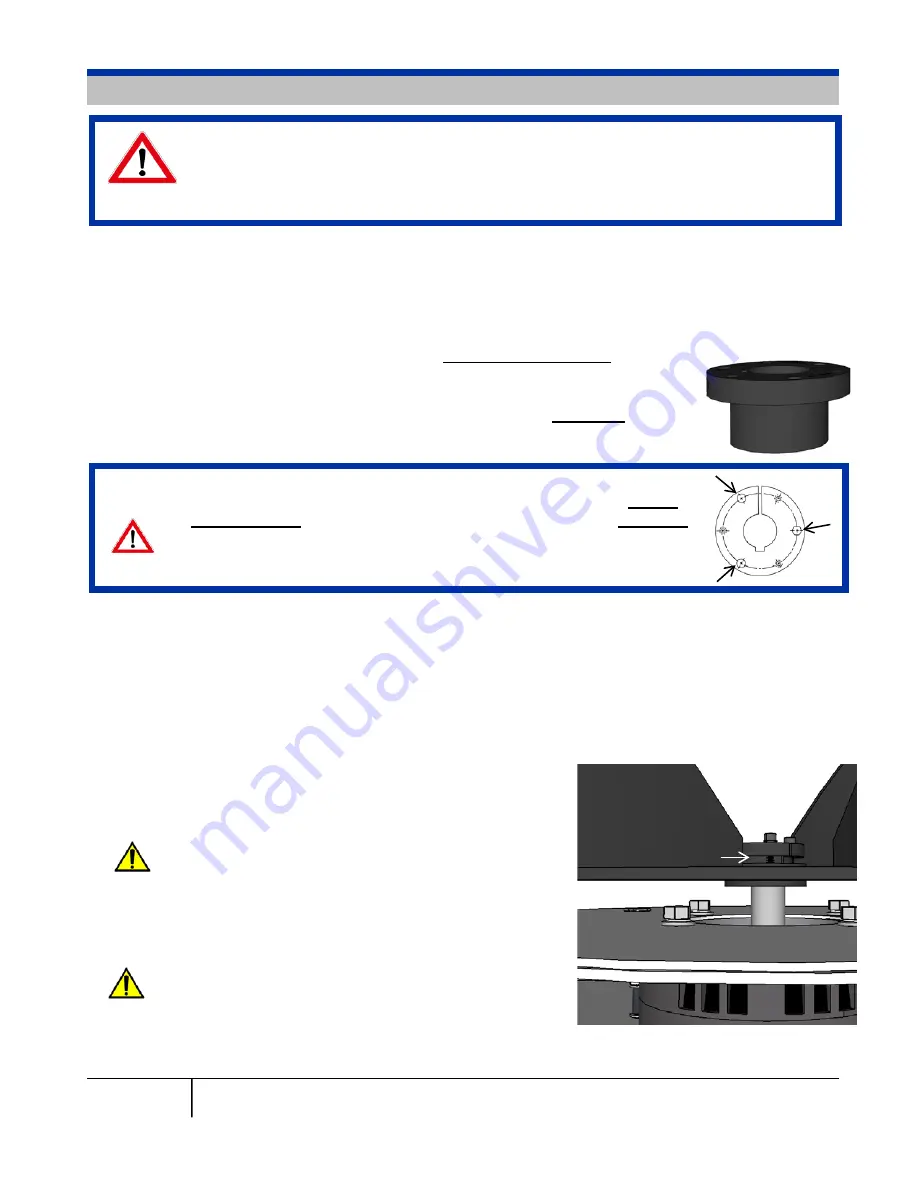

1. Locate the taper-lock bushing (and screws) installed on the impeller.

a. Remove it by inserting the (3) taper-lock bolts into the smaller, threaded holes in the

bushing and tightening them down until taper-lock releases from the impeller hub.

b. Pry the taper-lock slightly open by inserting a flat-head screwdriver into the slit in the side.

2. Loosely reattach the taper-lock bushing to the impeller:

a. Insert the (3) taper-lock bolts into the

larger, non-threaded

holes in

the taper-lock bushing.

b. Slide the taper-lock into the hub in the center of the impeller with the

wider side up, lining up the taper-lock bolts with the

threaded

holes

on the impeller.

c. Finger-tighten the bolts to secure them in place.

Make sure the taper-lock bolts are inserted through the larger,

non-threaded holes in the taper-lock bushing, into the threaded

holes of the impeller. The alternate set of holes is used for

impeller removal only.

3. Position the impeller:

a. Slide the impeller onto the motor shaft, with the taper-lock bushing facing up.

b. Insert the motor key and lightly tighten the setscrew using a

3

∕

32

” hex key until it cannot fall

out.

c. For single phase motors, lift the impeller so that the taper-lock is flush with the top of the

motor shaft.

d. For three phase motors, lift the impeller so that the taper-lock sits ¼” below the top of the

motor shaft.

4. Tighten the taper-lock bolts:

a. Consecutively tighten each taper-lock bolt by a ¼

revolution, until they are all tight.

The tightening of each bolt will cause the subsequent

bolts to feel as if they’ve loosened.

b. Repeat this process until each bolt is torqued to the

manufacturer’s specification of 5 ft/lbs.

Upon completion, there should be a minimum of ¼”

clearance between the back of the impeller and the

motor bolts intalled in the motor plate. There also may

be up to a

1

∕

8

” –

1

∕

4

” gap between the taper-lock

bushing and the impeller hub.

5. Firmly tighten the setscrew against the motor key using a

3

∕

32

” hex key.

≥

¼”

1

∕

8

” –

1

∕

4

”

This end UP