General Troubleshooting Guide

2

ClearWater Tech, LLC.

Toll Free: 1.800.262.0203 • Ph: 805.549.9724 • Fax: 805.549.0306

850-E Capitolio Way, San Luis Obispo, CA 93401 • email: service@cwtozone.com • www.cwtozone.com 110613

A color change from blue to pink or white indicates a possible failure of the air dryer or oxygen concentrator and will severely reduce ozone

output.

•

Ozone generators with model numbers that end in “/AD”: Perform the recommended annual maintenance. Replacement of the air dryer media

and all indicating media is a part of this maintenance. More information would be available in the unit’s manual.

•

Systems with oxygen concentrators: Perform the recommended annual maintenance to the ozone generator in addition to inspecting and verifying

the health of the associated oxygen concentrator. Information is available in the associated manual.

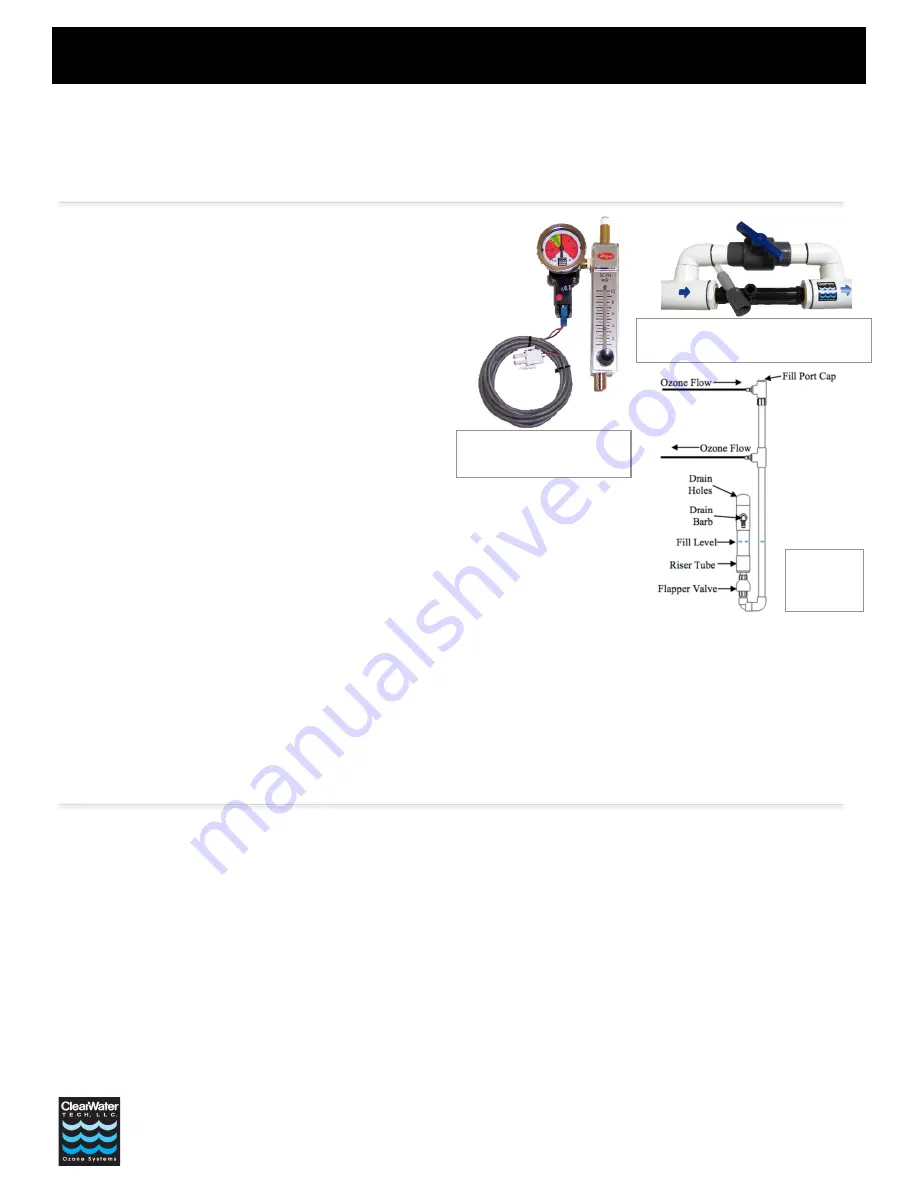

Air Leaks

Most installations of our ozone generators involve a venturi injector

plumbed into a pressurized water line; this creates a suction that draws the

ozone gas into the water.

If there are any breaks in the line, or any component, ambient air enters the

line supplanting the ozone, diluting it or if the leak is far enough back,

corrupting the dried air from the air prep. Any of these things will result in

lowering the ozone output of a system.

If a gauge assembly installed on the ozone generator

, insure the needle

is kept between -3 to -8”Hg. This is color-coded to a “green” area of the

gauge.

•

Adjust the black knob at the base of the airflow gauge to move the

needle within the green range.

o

If the needle moves freely within the green range, there is no

leak. The gas flowing through the ozone generator is getting into the water through the venturi

injector.

o

If the needle cannot be brought into the green range, or adjustments to the black knob cause the

needle to move to zero (it has to be closed most of the way to bring the needle barely into the green)

there may be an air leak.

Finding an air leak, or no gauge assembly installed,

confirm the level of vacuum at the injector is

maintained throughout the ozone system.

•

Deny power to the ozone generator.

•

Disconnect the tubing at the injector and place your thumb over the injector fitting. Use the tactile suction present to give you a baseline level of

suction.

•

Compare this level of suction to each point of tubing connections after reconnecting the injector.

•

Proceed to the end of each tubing connection starting from the injector back to the air preparation system.

o

Specifically check before and after vacuum break, if installed. This is a water trap to keep the ozone generator from getting wet if the check

valves fail. In order to remain sealed, there needs to be water on top of the white PVC flapper valve.

o

If vacuum is felt before the ozone generator, but is not detected after it; our leak is obviously within the ozone generator. Insure the power

cord is disconnected and remove the cover of the unit. Continue to check within the ozone generator, before and after the reaction chambers

is an ideal test.

By now, you’ve verified there are no leaks or have found an area that is leaking. Consult with your distributor or ClearWater Tech to find out what is

involved in resolving the leak (usually maintenance).

Water Chemistry

This area is typically explored when we suspect low ozone output, and the first three sections show to have no issues.

Abnormal pH

7.2 pH is optimal for ozone, the farther you are away from 7.2 you will experience lower ozone oxidation and ppm retention time.

Higher temperature

The hotter the air or water is, the faster ozone will convert back to oxygen. Anything over 85 degrees F will be considered 'hot' by these systems. As

temperatures will normally go over this level depending on season or heated pools, all ozone systems are typically oversized to take this into

consideration.

Atmospheric breaks

While pressurized in a contact tank or in the pipe, ozone will oxidize the water and build up a small residual ppm level before converting back to

oxygen.

If the pressure is suddenly lost due to being introduced to an open (atmospheric) tank or a water feature such as a waterfall, we can expect the ozone

to jump out of solution of the water. Oxidation and ppm retention will continue, but at a reduced level in and after this point.

Vacuum

break

assembly

Gauge assembly including

vacuum switch

Injector manifold with disconnected

check valve assembly