13

Revision date: 08.08.14

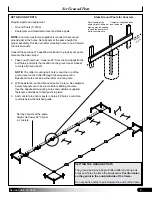

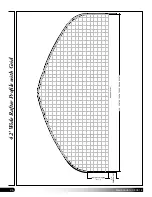

Finished Grade

Rope or

Cable

Frame Assembly

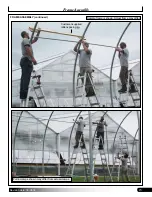

FRAME ASSEMBLY

Use the diagrams and information that follows to assemble the main frame.

ATTENTION:

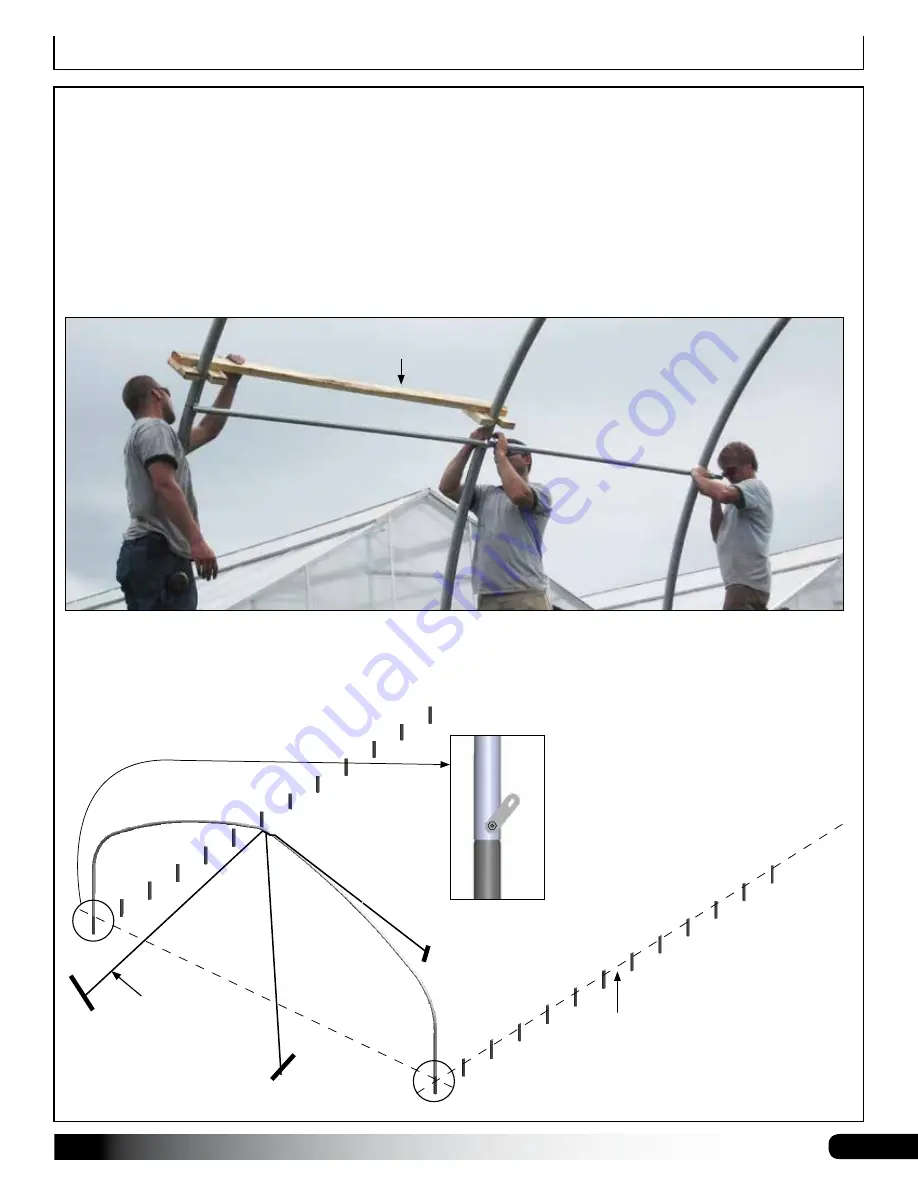

Rafters are heavy.

Always lift rafter from two separate points to prevent damage and injury.

Examine the site to determine the best way to move the rafters into position and to set them onto the ends of each set

of ground posts. Do not set rafters into position until the ground post concrete has set.

Optional, but recommended—especially for long buildings: Build a Rafter-Spacing Jig. (Customer supplies materials.)

A spacing jig saves time and helps to evenly space the rafters. Jig sets the on-center spacing of rafters. Examine the

photo below and use it to build a jig to space rafters during purlin installation. Use 2" x 4" lumber and wood fasteners.

Customer-supplied

rafter-spacing jig.

ATTENTION:

Anchor the first rafter in place using bracing, rope/cable, or a lift.

Do not allow the first rafter to stand

without bracing until additional rafters are set and purlins are installed

.

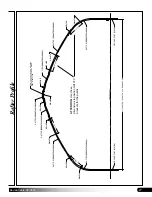

Connect rafters to ground posts using 105370B (1/2" x 4-1/2") bolts and FALB08B nuts.

Position nuts to the inside.

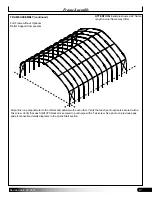

IMPORTANT:

Plumb the end rafter before

bracing it in place and installing other rafters.

ATTENTION:

Before adding

the nut to the 1/2" bolt, slide a

PGBRKAAS01 cable bracket onto

the bolt

at each end rafter

. Then

add the nut and tighten. See also

the details on the next page.