750-297

Profire E/LNE Series Manual

1-5

Introduction

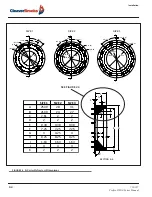

1.6.5 — Oil Metering

Fuel oil under nominal pressure in the circulating loop flows to the adjustable positive displacement (volumetric

metering unit). Oil metering is accomplished by changing the piston stroke by means of an eccentric shaft and pin

assembly. The pistons reciprocate in a rotor assembly, turning in a hardened steel sleeve having oil inlet and discharge

slots. During each revolution the pistons go through the following cycle:

1.

Inlet Cycle

. The piston is at the bottom dead center position. At this position, the cavity between the top of the

piston and the outside diameter of the rotor fills with oil.

2.

Discharge Cycle

. (180º from inlet cycle) The piston is at the top dead center position. At this position, the oil is

forced out of the discharge port to the nozzle. The piston stroke length is determined by the position of the eccentric

shaft and plate. The piston adjustment plate is positioned by an adjustable eccentric shaft. The eccentric shaft is

positioned by the modulator through adjustable linkage. Counterclockwise rotation of the eccentric shaft increases

the piston stroke (more oil delivered to nozzle); clockwise rotation decreases the amount of oil delivered. When the

eccentric shaft is stationary, at any position, the stroke of the pistons remains constant delivering a constant volume

of oil regardless of viscosity.

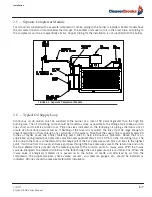

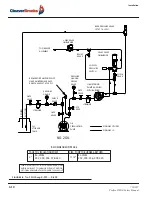

1.6.6 — Separate Compressor Module

EL and ELG burners have a burner mounted oil metering unit and a separate compressor module. The system functions

as follows:

Air is supplied by a positive displacement rotary vane compressor. This provides a constant volume of atomizing air

regardless of pressure. The compressor module includes motor, air-oil reservoir tank, air filter, and lube oil cooling coil.

Air enters the compressor through the filter. The air flows from the compressor into the air-oil separating and reservoir

tank. Filtering material and baffles separate the lube oil from the compressed air. The tank air pressure forces

lubricating oil from the tank to the compressor to lubricate bearings and vanes. A sight glass indicates the level of

lubricating oil in the air/oil reservoir. Lubricating oil must be visible in the gauge glass at all times. Air compression

heat is absorbed in part by the flow of lube oil, creating a hot oil mist. The air/oil mist is cooled by a coil assembly.

Lube oil is also cooled before entering the compressor.

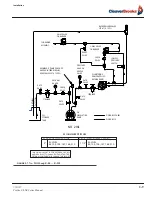

Fuel is delivered to the positive displacement metering pump at 10 to 15 psi. Metered oil is delivered to the common

port of a 3-way solenoid valve for transfer to the burner nozzle through the normally closed port or back to the storage

tank through the normally open port. During pre- and post-purge, metered oil is returned to the tank. During normal

firing, all metered oil is delivered to the nozzle. For the description of typical fuel oil piping installations, see Chapter 2.

Air enters a rotary vane compressor through an air cleaner where it is compressed to atomizing pressure. Air flows from

the compressor to an air/oil tank which serves the multiple purpose of dampening air pulsation, lube oil mist recovery,

lube oil and atomizing air storage. The compressor rotor is cooled and lubricated continuously by oil under pressure

from the air/oil tank. Oil vapor is extracted by a mist eliminator in the upper section of the tank. Atomizing air from the

upper tank section is delivered to the nozzle at a constant volume. Air pressure increases as the burner firing rate

increases. Atomizing pressure may be adjusted by the needle valve located on the air-oil pump. The valve allows air to

be bled from the tank to the compressor inlet. Delivery rate of the fuel oil metering pump is controlled by the

modulating motor through adjustable linkage.