Operation

3-6

750-297

Profire E/LNE Series Manual

3.8.2 — Oil Burners

1.

Set the fuel selector switch to “OIL.” On initial startup of a combination burner, it is recommended that oil firing be

adjusted before gas firing. The gas low firing rate is set to match the oil low fire rate.

2.

Be sure the ON-OFF switch is in the “OFF” position and the fuel selector switch is on “OIL.”

3.

Actuate the manual reset button of the flame safeguard control to close the safety switch contacts.

4.

Be sure the MANUAL-AUTO switch in the “MANUAL” position.

5.

Set the manual modulating control potentiometer in the “LOW FIRE” position.

6.

Open the pilot gas valve (if used).

7.

Set the ON-OFF switch to “ON.” The burner will start and pre-purge. After pre-purge, the ignition transformer and

the gas pilot are energized. Before proceeding, conduct electrical interference and pilot turndown tests if not

previously done.

8.

Observe the primary atomizing air pressure gauge on the air/oil tank. The gauge reading should be approximately 10

psi during pre-purge.

9.

When the pilot flame is proven, the programmer will proceed to the main flame position. Allow the burner to

operate in low fire, to warm the boiler before moving to high fire. Typically, for No. 2 oil, CO

2

is 8% to 11% at low

fire.

10.

Turn the manual potentiometer switch to the “HIGH FIRE” position. Check the high fire combustion at this point.

Do not disturb previously established low fire adjustment.

11.

Allow the burner to return to the low fire position before adjusting high or intermediate settings. The primary

atomizing air pressure will increase automatically with the oil flow rate. Typically, for No. 2 oil, CO

2

is 10% to 13%

at high fire.

When conditions covered above are assured, refer to Sections 3.9 and 3.10.

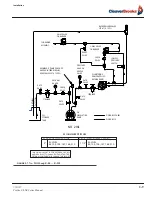

3.9 — Normal Operation

Normal operation must be with the MANUAL-AUTO switch set on “AUTO.”

In automatic operation, the operating cycle always proceeds sequentially through pre-purge, pilot ignition, main flame

ignition, run, and post-purge. The length of the purge and ignition trial vary according to the type of programmer used.

During the run cycle, burner input is regulated to the load demand by the modulating pressure or temperature control

on the boiler. The burner will continue to modulate until the operating pressure or temperature is reached.

Programmer control operation should be tested when the burner is initially placed into service, when a control is

replaced, and at scheduled intervals in the maintenance program.

Refer to adjustment procedures and maintenance instruction given in Chapters 4 and 5.

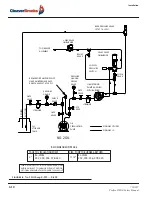

3.10 — Shutdown

When the operating limit control setting is reached or the burner switch is in the “OFF” position, the following

sequence occurs: