750-297

Profire E/LNE Series Manual

4-5

Adjustments

9.

The nozzle is not plugged or carboned. This will show up as excessive primary air pressure.

10.

The oil bypass valve is not bypassing the metered fuel oil.

Internal wear of the pump may take place due to the presence of dirt in the oil and in time this will result in excessive

clearances which reduce the pump capacity.

If the oil metering pump fails to deliver capacity or meters erratically, replace the oil and air pump as a unit and return

the old pump for repair or exchange (where allowed).

4.5.2 — Atomizing Air Pressure

Atomizing air in the air/oil tank is regulated by adjusting valve in the return air line on integral metering units or in the

air inlet on air compressor module burners. The air pressure is indicated by the pressure gauge at the air/oil tank.

A minimum of 10 psi air pressure in low fire is suggested. As the firing rate increases, the air pressure also increases.

Air pressure will be less with light oils. If any change in atomizing air pressure is made, check ignition several times for

reliable light off. Adjustments should be set to obtain reliable ignition with best low and high fire combustion results.

If the required atomizing air pressure cannot be maintained, a lack of lubricating oil may be the cause or the intake filter

may be dirty.

4.5.3 — Atomizing Air Proving Switch

The knurled nut between the switch and bellows is turned in to raise pressure setting. The minimum amount of

atomizing air is during pre- and post-purge. During pre-purge, adjust switch until it breaks the circuit. Readjust the

switch above this circuit breakpoint to actuate under a condition of minimum pressure, but not so close as to cause

nuisance shutdowns. Since the pressure of the atomizing air is at minimum when no fuel is present at the nozzle,

adjustment of the switch should be made while the unit is purging, but not firing.

4.5.4 — Low Oil Pressure Switch

The low oil pressure switch is adjusted at the minimum setting of 4 psi. Turning the knob clockwise will increase

pressure, counterclockwise will decrease pressure.

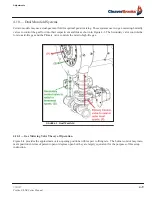

4.6 — Linkage and Modulating Motor

The linkage consists of adjustable cams, levers, rods and ball joints that transmit motion from the modulating motor to

the air damper, gas butterfly valve, and oil metering unit. When properly adjusted, coordinated movement of the air and

fuel control devices provide proper fuel/air ratios through the firing range. In linkage adjustments, several important

factors serve as guides:

•

The modulating motor must be able to complete its full travel range. Restrictions will damage the motor and/or the

linkage.

•

Lever and rod adjustments should be made with the motor in the low fire position.

The modulating motor will be stopped at the end of its stroke by an internal limit switch. Combustion gas analysis

indicates the air to fuel ratio and the degree of complete combustion. The closer the rod comes to parallel with the lever,

the slower the rod moves.The angles of the driven levers on the jackshaft can be adjusted to vary the rate