Maintenance

5-2

750-297

Profire E/LNE Series Manual

5.2.1 — Programming Control

This control requires no adjustment, nor should any attempt be made to alter contact settings or timing logic. Those

programmers with contacts may require occasional cleaning. If so, follow instructions given in the manufacturer's

bulletin. Never use abrasive materials. The manufacturer's bulletin also contains troubleshooting information. The

flame detector lens should be cleaned as often as conditions demand. A periodic safety check procedure should be

established to test the complete safeguard system. Tests should verify safety shutdown with a safety lock out upon

failure to ignite the pilot or the main flame, and upon loss of flame. Each of these conditions should be checked on a

scheduled basis. The safety check procedures are contained in the manufacturer's bulletin.

5.3 — Impeller and Inlet Cone

Proper clearance between the impeller and the inlet housing set at 3/8” nominal. Adjust the inlet cone so it is centered

in the inlet of the impeller and tighten the bolts. There should be no contact between the inlet cone and the impeller.

Inserting a bar through the impeller blade and using it as a lever will only damage the blade and also void the impeller

warranty.

5.4 — Firing Head Inspection

Disconnect the damper linkage, release the impeller housing latches, and swing the housing open for access to the

firing head. Inspect the flame scanner lens to be sure it is clean Inspect the lead wire to the ignition electrode. It must be

firmly attached and the insulation should be clean and free of cracks. The oil nozzle should be inspected periodically

depending on the grade of oil burned and the cleanliness of the environment.

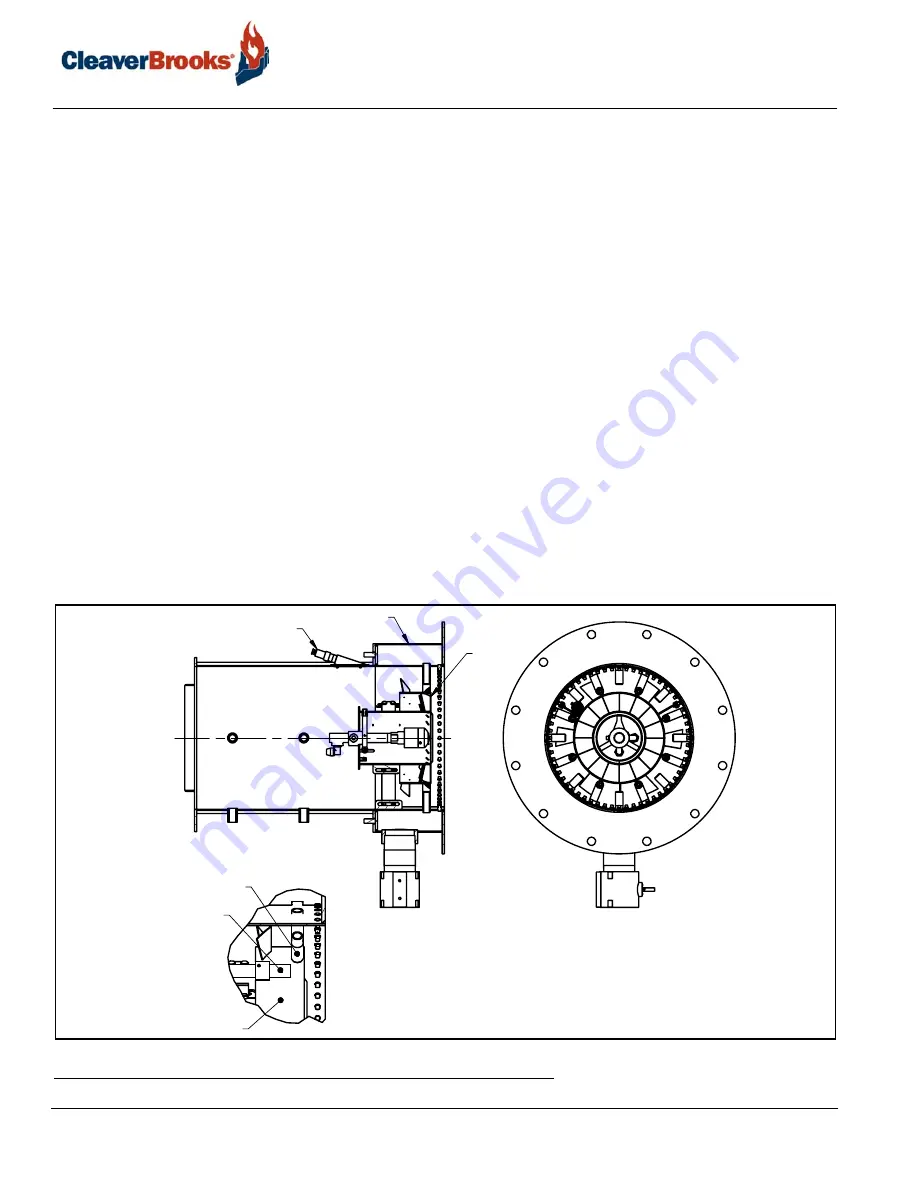

FIGURE 5-1.

Firing Head Assembly

PILOT

DIFFUSER

GAS SPUD

GAS MANIFOLD

SCANNER

DIFFUSER

FIRING HEAD ASSEMBLY