Page 16

Section 5 Troubleshooting Guide

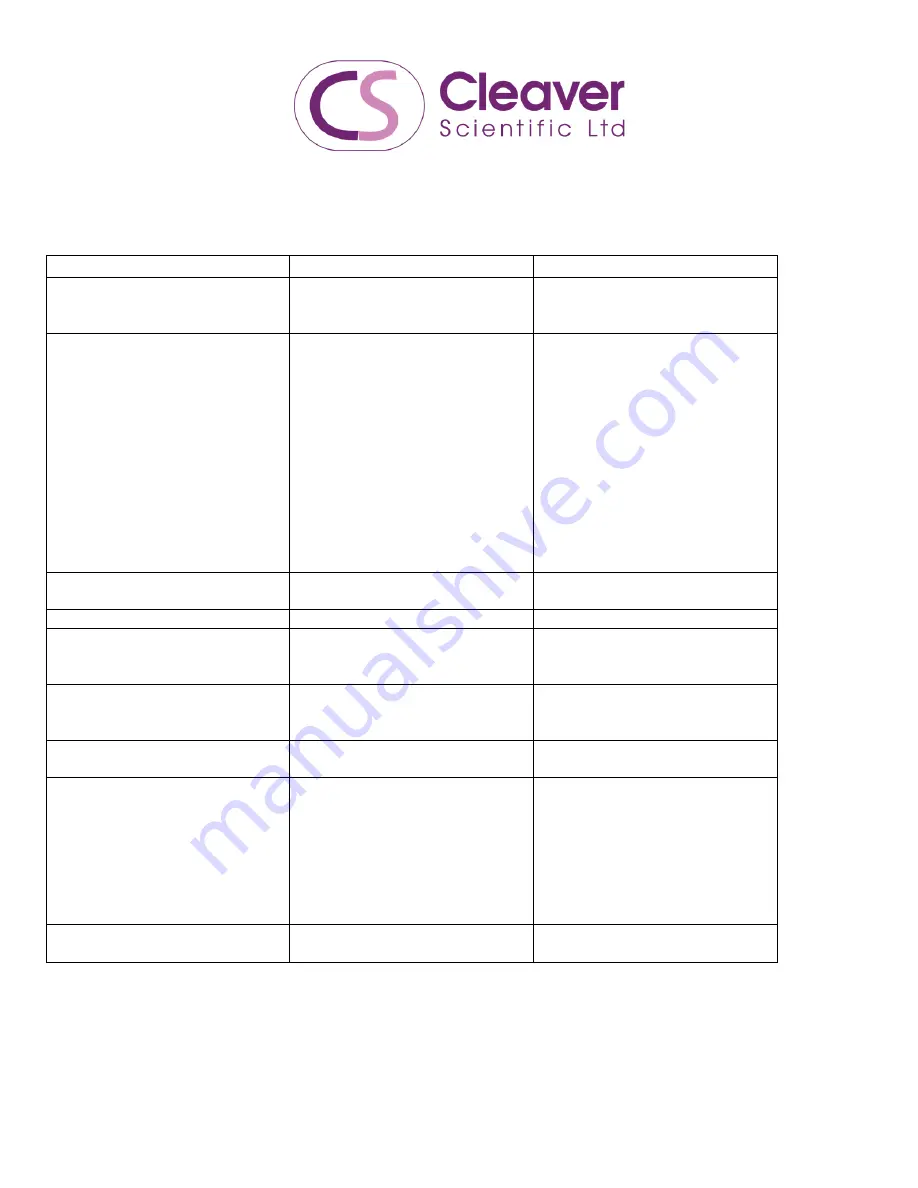

Problem

Cause

Solution

Bands sharp but not enough bands

seen

Gel agarose percentage too high

Incomplete digestion

Decrease agarose percentage.

Review enzyme activity, digest

further.

Band smearing and streaking

Agarose has improper endosmosis

Salt concentration in sample too high

Excessive power and heating

Sample spilled out of well

Incomplete

digestion,

nuclease

contamination, bad enzyme

Sample wells cast through the gel.

Sample leaks along bottom of

running surface

Consult Cleaver Scientific about

agarose.

Reduce salt concentration to ≤0.1M.

Reduce voltage. See electrophoresis

instructions.

Apply sample carefully. Increase gel

thickness for large sample volumes.

Adjust comb height.

Heat

sample.

Review

enzyme

activity. Digest sample further.

Comb should be placed to 1 to 2 mm

above the base of the running

surface.

Curved line or distortion of bands

Bubbles in sample wells

Remove

bubbles

prior

to

electrophoresis.

Curved bands, smiles

Sample overload

Reduce load.

Differential relative mobilities

Sample spilled out of wells

Unit not leveled

Samples should have proper density.

Apply carefully.

Level unit. Use a steady work bench.

Gels crack

Too high voltage gradient, especially

with low melting temperature

agarose or low gel strength gels

Reduce voltage. Run gel at lower

temperature.

High MW bands sharp; low MW

bands smeared

Gel agarose percentage too low

Increase agarose percentage. Switch

to polyacrylamide.

Ragged bands

Sample density incorrect

Sample well deformed

Excessive power or heating

See sample application instructions.

Carefully remove comb, especially

from soft gels. Make sure gel has

solidified.

Cooling soft gels aids in comb

removal.

Reduce voltage. See electrophoresis

instructions.

Slanted lanes (bands)

Gel not fully solidified

Comb warped or at an angle

Gel to solidify for at least 30-45min.

Check alignment of comb.