Chapter 6 — Adjustment Procedures

6-20

Part No. 750-184

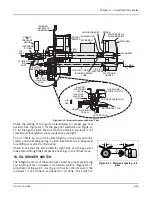

Since the input of combustion air is ordinarily fixed at any given

point in the modulating cycle, the flue gas reading is determined by

varying the input of gas fuel at that setting. The adjustment is made

to the metering cam by means of adjusting screws, which are turned

outward (counterclockwise from the hex-socket end) to increase the

flow of fuel, and inward (clockwise from the hex-socket end) to

decrease it. Flow rate is highest when the cam follower assembly is

closest to jackshaft.

Through the manual flame control switch, position the cam so that

the adjusting screw adjacent to the end or high fire screw contacts

the cam follower. Perform a combustion analysis at this point. If an

adjustment is necessary, turn the adjustment screw accordingly to

increase or decrease fuel flow. Take a combustion reading to verify

input. Repeat as necessary until the desired flow is obtained.

Repeat the process, stopping at each adjusting screw, until the low

fire adjusting screw is reached.

Note: Do not use any lubricant on the adjusting setscrews.

The set screws have a nylon locking insert intended to

provide locking torque and resistance to loosening and

a lubricant could damage equipment.

Standard Burner Low Fire Adjustment

The fuel input should be adjusted using the low fire cam screw, to

approximately 25% of that at high fire (Table 6-6). At low fire the

O

2

flue gas reading should be between 6-7%.

It may be necessary to readjust the setting of the low fire stop screw

to obtain the proper air/fuel ratio at the low fire rate. To ensure that

the low fire position of the gas butterfly valve is always the same,

allow one turn of the stop screw for overtravel.

If the air damper needs to be adjusted in order to provide the correct

low fire air/fuel ratio, combustion must be rechecked at higher firing

rates and adjusted as required.

If all cam screws are properly adjusted, none will deviate from the

general overall contour of the cam face.

R. LOW-GAS-PRESSURE SWITCH

Adjust the scale setting to slightly below the normal burning

pressure. The control circuit will be broken when pressure falls

below this point. Since gas line distribution pressure may decrease

under some conditions, shutdowns may result if the setting is too

close to normal. However, regulations require that the setting may

not be less than 50% of the rated pressure downstream of the

regulator.

Manual resetting is necessary after a pressure drop

. Press the reset

lever after pressure is restored. Be sure that the mercury switch

equipped control is level.

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...