Chapter 1 — Basics of Firetube Operation

1-4

Part No. 750-184

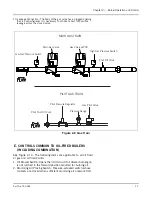

The IFGR system mixes a portion of the relatively cool flue gas from

the exit of the fourth-pass tubes with the incoming combustion air

to reduce the furnace flame temperature, thereby reducing NOx

emissions. In this approach, the combustion air fan handles both

the combustion air and the recirculated flue gases. Accordingly, this

method is called Induced Flue Gas Recirculation (IFGR), because

the flue gas is “induced” into the fan inlet.

The LE option, with its various levels of IFGR systems, can affect

the selection of the combustion air fan, motor, burner, and other

components. Several different system configurations are available,

depending on the requirements for NOx emissions and the fuels

used. All systems use similar primary components, but may have

different linkage controls, IFGR damper, fan, and motor sizes.

Always order genuine Cleaver-Brooks parts from your local Cleaver-

Brooks authorized representative.

The boiler and related equipment installation are to be in

compliance with the standards of the National Board of Fire

Underwriters. Installation should also conform to state and local

codes governing such equipment. Prior to installation, the proper

authorities having jurisdiction are to be consulted, permits

obtained, etc. All boilers in the above series comply, when equipped

with optional equipment, to Industrial Risk Insurers (IRI), Factory

Mutual (FM), or other insuring underwriters requirements.

B. THE BOILER

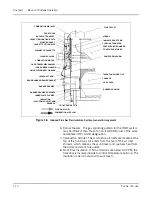

The Model CB/CB-LE boiler is a packaged firetube boiler of welded

steel construction and consists of a pressure vessel, burner, burner

controls, forced draft fan, damper, air pump, refractory, and

appropriate boiler trim.

The horsepower rating of the boiler is indicated by the numbers

following the fuel series. Thus, CB700-200 indicates a gas-fired

200 hp boiler.

The firetube construction provides some characteristics that

differentiate it from other boiler types. Because of its vessel size, the

firetube contains a large amount of water, allowing it to respond to

load changes with minimum variation in steam pressure.

Firetube boilers are rated in boiler horsepower (BHP), which should

not be confused with other horsepower measurements.

Hot water is commonly used in heating applications with the boiler

supplying water to the system at 180

°

F to 220

°

F. The operating

pressure for hot water heating systems usually is 30 psig to 125

psig.

Steam boilers are designed for low pressure or high pressure

applications. Low pressure boilers are limited to 15 psig design, and

are typically used for heating applications. High pressure boilers are

typically used for process loads and can have a design pressure of

75 to 350 psig.

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...