Chapter 1 — Basics of Firetube Operation

Part No. 750-184

1-5

Steam and hot water boilers are defined according to design

pressure and operating pressure. Design pressure is the maximum

pressure used in the design of the boiler for the purpose of

calculating the minimum permissible thickness or physical

characteristics of the pressure vessel parts of the boiler. Typically,

the safety valves are set at or below design pressure. Operating

pressure is the pressure of the boiler at which it normally operates.

The operating pressure usually is maintained at a suitable level

below the setting of the pressure relief valve(s) to prevent their

frequent opening during normal operation.

The type of service that your boiler is required to provide has an

important bearing on the amount of waterside care it will require.

!

Caution

Waterside care is of prime importance. For specific information or

assistance with your water treatment requirements, contact your

Cleaver-Brooks service and parts representative. Failure to follow

these instructions could result in equipment damage

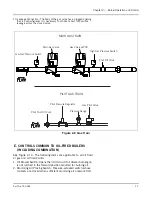

Feedwater equipment should be checked and ready for use. Be sure

that all valves, piping, boiler feed pumps, and receivers are installed

in accordance with prevailing codes and practices.

Water requirements for both steam and hot water boilers are

essential to boiler life and length of service. Constant attention to

water requirements will pay dividends in the form of longer life, less

down-time, and prevention of costly repairs. Care taken in placing

the pressure vessel into initial service is vital. The waterside of new

boilers and new or remodeled steam or hot water systems may

contain oil, grease or other foreign matter. A method of boiling out

the vessel to remove accumulations is described in Chapter 3.

The operator should be familiar with Chapter 3 before attempting to

place the unit into operation.

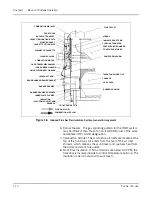

C. CONSTRUCTION

Steam boilers designed for 15 psig and hot water boilers designed

for 250

°

F at 125 psi or less are constructed in accordance with

Section IV, Power Boilers, of ASME Code.

Steam boilers designed for operating pressures exceeding 15 psig

are constructed in accordance with Section 1, Power Boilers, of the

ASME code. Hot water boilers designed for operating temperatures

above 250

°

F or 125 psi are likewise built to ASME code.

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...