Chapter 2 — Burner Operation and Control

Part No. 750-184

2-5

subsequent setting of fuel input throughout the firing range. It

has no control over the firing rate when the manual-automatic

switch is set on “automatic.”

11.Burner Switch (Figure 2-8): A manually operated start-stop

switch for directly starting and stopping operation of burner.

12.Flame Detector: Monitors gas or oil pilot and energizes the

programmer flame relay in response to a flame signal. It

continues to monitor main flame (oil or gas) after expiration of

pilot providing period. A standard equipped boiler has a lead

sulfide (infrared sensitive) detector.

13.Combustion Air Proving Switch: A pressure-sensitive switch

actuated by air pressure from the forced draft fan. Its contacts

close to prove presence of combustion air. The fuel valves cannot

be energized unless this switch is satisfied. The combustion air

proving switch is provided on all gas fired or combination gas-oil

burners. An oil fired boiler does not normally have a separate

switch but utilizes the atomizing air proving switch to the same

effect, since the presence of atomizing air from the air pump,

which is belt driven from the blower motor, is evidence of blower

operation.

14.Alarm: Sounds to notify the operator of a condition requiring

attention. The alarm is available as optional equipment.

15.Stack Thermometer (Figure 2-6): Indicates temperature of

vented flue gases.

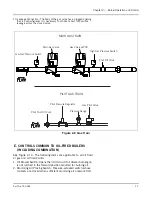

16.Diffuser (Figure 2-7): A circular plate, located at the furnace end

of the burner drawer, that imparts a rotary swirling motion to

combustion air immediately prior to its entering the flame, thus

providing a thorough and efficient mixture with the fuel.

17.Rotary Air Damper (Figure 2-7): Provides accurate control of

combustion air in proportion to fuel input for various load

demands. It consists of two concentric cylinders with openings.

The outer is stationary. The inner is rotated, under control of the

modulating motor, to vary the effective size of the openings

where they overlap.

18.Indicator Lights (Figure 2-8): Provide visual information of boiler

operation as follows (indicator lights vary with controls

provided):

• Flame Failure

• Load Demand

• Fuel Valve (valve open)

• Low Water

Figure 2-6 Stack Thermometer

Figure 2-7 Diffuser & Damper

Diffuser

Rotary Air

Damper

Figure 2-8 Control Panel

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

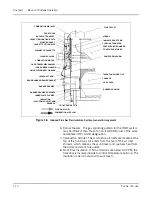

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

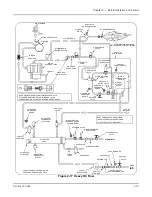

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...