750-204

Profire D/LND

4-1

CHAPTER 4

Adjustments

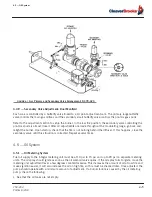

4.1 — Overview

While each burner is tested at the factory for correct operation before shipment, variable conditions such as

burning characteristics of the fuel used and operating load conditions may require further adjustment after instal-

lation to assure maximum operating efficiency.

Prior to placing the boiler into initial service, a complete inspection should be made of all controls, connecting

piping, wiring and all fastenings such as nuts, bolts, and setscrews to be sure that no damage or mis-adjust-

ments occurred during shipping and installation.

A combustion efficiency analysis made during the initial startup will help to determine what additional adjust-

ments are required in a particular installation.

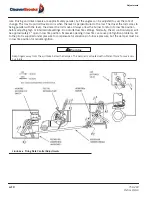

4.2 — Combustion Adjustment on Gas and Oil

Efficient combustion cannot be properly judged by flame appearance, although it may help in making preliminary

settings.

The proper settings of air-fuel ratios must be determined by flue gas analysis. Combustion gas analysis indicates

the air to fuel ratio and the degree of complete combustion. Instruments are available to measure carbon dioxide

(CO

2

), oxygen (O

2

), and carbon monoxide (CO).

4.2.1 — Stack Temperature

Net stack temperature is obtained by subtracting the ambient temperature from the flue gas temperature. A high

net stack temperature indicates wasted heat. Stack temperature should be as low as possible without causing

flue gas condensation.

Stack heat loss can be reduced by decreasing either the temperature or the volume of the flue gas, or both. Flue

gas temperature is reduced by improving heat transfer or by reducing excess combustion air. A certain amount of

excess air is necessary to complete combustion. More efficient burners require minimum excess air.

Summary of Contents for ProFire D Series

Page 2: ......

Page 8: ......

Page 16: ...viii 750 204 Profire D LND...

Page 30: ...Installation 2 2 750 204 Profire D LND FIGURE 2 1 Recommended Scotch Marine Chamber Dimensions...

Page 39: ...750 204 Profire D LND 2 11 2 13 Installation Checklist FIGURE 2 7 Recommended Pipe Size...

Page 40: ...Installation 2 12 750 204 Profire D LND FIGURE 2 8 Recommended Pipe Size...

Page 42: ...Installation 2 14 750 204 Profire D LND FIGURE 2 10 Recommended Pipe Size...

Page 43: ...750 204 Profire D LND 2 15 2 13 Installation Checklist FIGURE 2 11 Recommended Pipe Size...

Page 44: ...Installation 2 16 750 204 Profire D LND FIGURE 2 12 Recommended Pipe Size...

Page 45: ...750 204 Profire D LND 2 17 2 13 Installation Checklist FIGURE 2 13 Recommended Pipe Size...

Page 46: ...Installation 2 18 750 204 Profire D LND FIGURE 2 14 Recommended Pipe Size...

Page 50: ...Installation 2 22 750 204 Profire D LND...

Page 69: ...750 204 Profire D LND 4 11 4 8 Firing Rate Controls FIGURE 4 7 Motor Rotations...

Page 70: ...Adjustments 4 12 750 204 Profire D LND...

Page 82: ...Maintenance 5 12 750 204 Profire D LND...

Page 88: ...Troubleshooting 6 6 750 204 Profire D LND...

Page 98: ...Flue Gas Recirculation 8 6 750 204 Profire D LND FIGURE 8 4 FGR Piping and Valve Sizes...

Page 100: ...Flue Gas Recirculation 8 8 750 204 Profire D LND FIGURE 8 6 20 PPM Head Assembly...

Page 106: ...Parts Lists and Drawings 9 6 750 204 Profire D LND 9 4 2 Blast Tube Assembly D378 420...

Page 108: ...Parts Lists and Drawings 9 8 750 204 Profire D LND 9 4 3 Blower Housing Assembly D42 175...

Page 110: ...Parts Lists and Drawings 9 10 750 204 Profire D LND 9 4 4 Blower Housing Assembly D210 336...

Page 112: ...Parts Lists and Drawings 9 12 750 204 Profire D LND 9 4 5 Blower Housing Assembly D378 420...

Page 114: ...Parts Lists and Drawings 9 14 750 204 Profire D LND 9 4 6 Compressor Set D42 145...

Page 116: ...Parts Lists and Drawings 9 16 750 204 Profire D LND 9 4 7 Compressor Set D175 336...

Page 118: ...Parts Lists and Drawings 9 18 750 204 Profire D LND 9 4 8 Compressor Set D378 420...

Page 120: ...Parts Lists and Drawings 9 20 750 204 Profire D LND 9 4 9 Control Package Fireye...

Page 122: ...Parts Lists and Drawings 9 22 750 204 Profire D LND 9 4 10 Control Package Honeywell...

Page 124: ...Parts Lists and Drawings 9 24 750 204 Profire D LND 9 4 11 Damper Assembly D42 420...

Page 126: ...Parts Lists and Drawings 9 26 750 204 Profire D LND 9 4 12 Damper Assembly LND42 420...

Page 128: ...Parts Lists and Drawings 9 28 750 204 Profire D LND 9 4 13 Drawer Assembly D42 63...

Page 130: ...Parts Lists and Drawings 9 30 750 204 Profire D LND 9 4 14 Drawer Assembly D84 145...

Page 132: ...Parts Lists and Drawings 9 32 750 204 Profire D LND 9 4 15 Drawer Assembly D175 336...

Page 134: ...Parts Lists and Drawings 9 34 750 204 Profire D LND 9 4 16 Drawer Assembly D378 420...

Page 136: ...Parts Lists and Drawings 9 36 750 204 Profire D LND 9 4 17 Firing Head Assembly D42 420...

Page 139: ...750 204 Profire D LND 9 39 9 4 Parts Lists and Drawings 9 4 19 Oil Heater D42 420...

Page 146: ...Parts Lists and Drawings 9 46 750 204 Profire D LND 9 4 22 Oil Metering Assembly D378 420...

Page 156: ...750 204 Profire D LND...

Page 159: ......

Page 160: ......