750-204

Profire D/LND

4-3

4.4 — Gas System

4.4 — Gas System

4.4.1 — Gas Pressure

Gas must be supplied at a pressure high enough to overcome the pressure loss in the burner gas train and fur-

nace pressure while running at full input. Refer to the nameplate inside the control panel for gas pressure require-

ments at the train inlet and manifold. The pressures listed are based on nominal 1000 Btu/cu. ft. natural gas at

elevations up to 2000 feet above sea level.

4.4.2 — Gas Flow

The volume of gas is measured in cubic feet as determined by a meter reading. The gas flow rate required

depends on the heating value (Btu/cu. ft.). The supplying utility can provide this information as well as pressure

correction factors. To determine the required number of cubic feet per hour of gas, divide burner input (Btu/hr.)

by the heating value (Btu/cu. ft.).

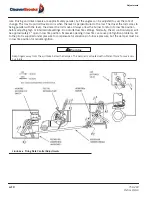

4.4.3 — Gas Pilot Flame Adjustment

The gas pilot flame is regulated by adjusting the pressure setting of the pilot regulator. Normal setting is 3” to 6”

W.C. when the pilot is burning. The flame must be sufficient to be proven by the flame detector and ignite the

main flame.

Although it is possible to visibly adjust the size of the pilot flame, obtain a proper DC volt or microamp reading of

the flame signal.

The flame safeguard amplifier has a meter jack for this purpose. At initial startup and during planned mainte-

nance, test the pilot flame signal, pilot turndown, and safety switch lockout.

4.4.4 — Main Gas Pressure Regulator

The gas pressure required at the burner manifold is the pressure that is required to fire the burner at its rated

capacity. The gas pressure regulator must be adjusted to achieve this pressure to assure full input. Refer to man-

ufacturer’s literature for regulator adjustment.

4.4.5 — Low Gas Pressure Switch

Turn the adjusting screw until indicator moves to a pressure setting slightly below the operating gas pressure. The

control will break a circuit if pressure is below this set point. The control should be finally adjusted to prevent

operation with low gas pressure, but not at a pressure so close to normal operating pressure that unnecessary

shutdowns occur. The switch must be manually reset after tripping. To reset, allow gas pressure to rise and press

the manual reset button.

NOTE:

When checking the input rate, make sure no other equipment is operating on the same meter.

An ultra-violet flame sensor electrical spark interference test must be performed after final adjustment. See Section

4.3 for additional information.

!

Warning

Summary of Contents for ProFire D Series

Page 2: ......

Page 8: ......

Page 16: ...viii 750 204 Profire D LND...

Page 30: ...Installation 2 2 750 204 Profire D LND FIGURE 2 1 Recommended Scotch Marine Chamber Dimensions...

Page 39: ...750 204 Profire D LND 2 11 2 13 Installation Checklist FIGURE 2 7 Recommended Pipe Size...

Page 40: ...Installation 2 12 750 204 Profire D LND FIGURE 2 8 Recommended Pipe Size...

Page 42: ...Installation 2 14 750 204 Profire D LND FIGURE 2 10 Recommended Pipe Size...

Page 43: ...750 204 Profire D LND 2 15 2 13 Installation Checklist FIGURE 2 11 Recommended Pipe Size...

Page 44: ...Installation 2 16 750 204 Profire D LND FIGURE 2 12 Recommended Pipe Size...

Page 45: ...750 204 Profire D LND 2 17 2 13 Installation Checklist FIGURE 2 13 Recommended Pipe Size...

Page 46: ...Installation 2 18 750 204 Profire D LND FIGURE 2 14 Recommended Pipe Size...

Page 50: ...Installation 2 22 750 204 Profire D LND...

Page 69: ...750 204 Profire D LND 4 11 4 8 Firing Rate Controls FIGURE 4 7 Motor Rotations...

Page 70: ...Adjustments 4 12 750 204 Profire D LND...

Page 82: ...Maintenance 5 12 750 204 Profire D LND...

Page 88: ...Troubleshooting 6 6 750 204 Profire D LND...

Page 98: ...Flue Gas Recirculation 8 6 750 204 Profire D LND FIGURE 8 4 FGR Piping and Valve Sizes...

Page 100: ...Flue Gas Recirculation 8 8 750 204 Profire D LND FIGURE 8 6 20 PPM Head Assembly...

Page 106: ...Parts Lists and Drawings 9 6 750 204 Profire D LND 9 4 2 Blast Tube Assembly D378 420...

Page 108: ...Parts Lists and Drawings 9 8 750 204 Profire D LND 9 4 3 Blower Housing Assembly D42 175...

Page 110: ...Parts Lists and Drawings 9 10 750 204 Profire D LND 9 4 4 Blower Housing Assembly D210 336...

Page 112: ...Parts Lists and Drawings 9 12 750 204 Profire D LND 9 4 5 Blower Housing Assembly D378 420...

Page 114: ...Parts Lists and Drawings 9 14 750 204 Profire D LND 9 4 6 Compressor Set D42 145...

Page 116: ...Parts Lists and Drawings 9 16 750 204 Profire D LND 9 4 7 Compressor Set D175 336...

Page 118: ...Parts Lists and Drawings 9 18 750 204 Profire D LND 9 4 8 Compressor Set D378 420...

Page 120: ...Parts Lists and Drawings 9 20 750 204 Profire D LND 9 4 9 Control Package Fireye...

Page 122: ...Parts Lists and Drawings 9 22 750 204 Profire D LND 9 4 10 Control Package Honeywell...

Page 124: ...Parts Lists and Drawings 9 24 750 204 Profire D LND 9 4 11 Damper Assembly D42 420...

Page 126: ...Parts Lists and Drawings 9 26 750 204 Profire D LND 9 4 12 Damper Assembly LND42 420...

Page 128: ...Parts Lists and Drawings 9 28 750 204 Profire D LND 9 4 13 Drawer Assembly D42 63...

Page 130: ...Parts Lists and Drawings 9 30 750 204 Profire D LND 9 4 14 Drawer Assembly D84 145...

Page 132: ...Parts Lists and Drawings 9 32 750 204 Profire D LND 9 4 15 Drawer Assembly D175 336...

Page 134: ...Parts Lists and Drawings 9 34 750 204 Profire D LND 9 4 16 Drawer Assembly D378 420...

Page 136: ...Parts Lists and Drawings 9 36 750 204 Profire D LND 9 4 17 Firing Head Assembly D42 420...

Page 139: ...750 204 Profire D LND 9 39 9 4 Parts Lists and Drawings 9 4 19 Oil Heater D42 420...

Page 146: ...Parts Lists and Drawings 9 46 750 204 Profire D LND 9 4 22 Oil Metering Assembly D378 420...

Page 156: ...750 204 Profire D LND...

Page 159: ......

Page 160: ......