Adjustments

4-4

750-204

Profire D/LND

4.4.6 — High Gas Pressure Switch

Turn the adjusting screw until the indicator moves to a pressure setting slightly above the maximum operating

gas pressure. The control will break a circuit if pressure exceeds this value. The control should be adjusted to

prevent operation with excessive gas pressure, but not at a pressure so close to normal operating pressure that

unnecessary shutdowns occur. This switch must be manually reset after tripping. To reset, allow the gas pressure

to drop and press the manual reset button.

4.4.7 — Gas Combustion Adjustment

After operating for a sufficient period of time to assure a warm boiler, make adjustments for most efficient com-

bustion. The butterfly gas valve directly controls the rate of flow. The low fire light-off setting should be regarded

as preliminary until proper gas pressure for high fire operation is established.

Determine the actual gas flow from a meter reading at high fire. With the butterfly valve open and with regulated

gas pressure set, the actual flow rate should be quite close to the required input. If corrections are necessary,

increase or decrease the gas pressure by adjusting the gas pressure regulator, following the manufacturer's direc-

tions for regulator adjustment.

When proper gas flow is obtained, take a flue gas analysis reading.

With the high fire air-fuel ratio established, the gas pressure regulator needs no further adjusting.

Recheck low fire and adjust if necessary.

Proper setting of the air/fuel ratios at all rates must be determined by combustion analysis. See Section 4.2 of

additional information.

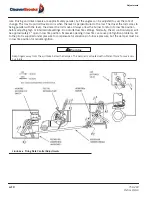

4.4.8 — Secondary Valve Adjustment: Gas Models D 378 & 420

The secondary valve feeds gas to the inner spuds. A slot in the valve stem in relationship to the shut/open scale

on the valve indicates the blade position. In the low fire starting position, the stem slot should be positioned at

the left hand 1/4 mark and travel in a counterclockwise direction to the mid fire shut position. Continuing in a

counterclockwise direction, the stem slot should stop at the right hand 1/4 mark. This is the high fire position.

Both low and high fire positions are approximate. Adjustments to the valve should be made on the secondary

valve linkage arm. To increase the travel, move the linkage arm closer to the pivot point. To decrease the travel,

move the linkage arm away from the pivot point. The primary valve which feeds the outer spuds should be

adjusted as normal.

NOTE:

Check for CO through the entire firing range.

Summary of Contents for ProFire D Series

Page 2: ......

Page 8: ......

Page 16: ...viii 750 204 Profire D LND...

Page 30: ...Installation 2 2 750 204 Profire D LND FIGURE 2 1 Recommended Scotch Marine Chamber Dimensions...

Page 39: ...750 204 Profire D LND 2 11 2 13 Installation Checklist FIGURE 2 7 Recommended Pipe Size...

Page 40: ...Installation 2 12 750 204 Profire D LND FIGURE 2 8 Recommended Pipe Size...

Page 42: ...Installation 2 14 750 204 Profire D LND FIGURE 2 10 Recommended Pipe Size...

Page 43: ...750 204 Profire D LND 2 15 2 13 Installation Checklist FIGURE 2 11 Recommended Pipe Size...

Page 44: ...Installation 2 16 750 204 Profire D LND FIGURE 2 12 Recommended Pipe Size...

Page 45: ...750 204 Profire D LND 2 17 2 13 Installation Checklist FIGURE 2 13 Recommended Pipe Size...

Page 46: ...Installation 2 18 750 204 Profire D LND FIGURE 2 14 Recommended Pipe Size...

Page 50: ...Installation 2 22 750 204 Profire D LND...

Page 69: ...750 204 Profire D LND 4 11 4 8 Firing Rate Controls FIGURE 4 7 Motor Rotations...

Page 70: ...Adjustments 4 12 750 204 Profire D LND...

Page 82: ...Maintenance 5 12 750 204 Profire D LND...

Page 88: ...Troubleshooting 6 6 750 204 Profire D LND...

Page 98: ...Flue Gas Recirculation 8 6 750 204 Profire D LND FIGURE 8 4 FGR Piping and Valve Sizes...

Page 100: ...Flue Gas Recirculation 8 8 750 204 Profire D LND FIGURE 8 6 20 PPM Head Assembly...

Page 106: ...Parts Lists and Drawings 9 6 750 204 Profire D LND 9 4 2 Blast Tube Assembly D378 420...

Page 108: ...Parts Lists and Drawings 9 8 750 204 Profire D LND 9 4 3 Blower Housing Assembly D42 175...

Page 110: ...Parts Lists and Drawings 9 10 750 204 Profire D LND 9 4 4 Blower Housing Assembly D210 336...

Page 112: ...Parts Lists and Drawings 9 12 750 204 Profire D LND 9 4 5 Blower Housing Assembly D378 420...

Page 114: ...Parts Lists and Drawings 9 14 750 204 Profire D LND 9 4 6 Compressor Set D42 145...

Page 116: ...Parts Lists and Drawings 9 16 750 204 Profire D LND 9 4 7 Compressor Set D175 336...

Page 118: ...Parts Lists and Drawings 9 18 750 204 Profire D LND 9 4 8 Compressor Set D378 420...

Page 120: ...Parts Lists and Drawings 9 20 750 204 Profire D LND 9 4 9 Control Package Fireye...

Page 122: ...Parts Lists and Drawings 9 22 750 204 Profire D LND 9 4 10 Control Package Honeywell...

Page 124: ...Parts Lists and Drawings 9 24 750 204 Profire D LND 9 4 11 Damper Assembly D42 420...

Page 126: ...Parts Lists and Drawings 9 26 750 204 Profire D LND 9 4 12 Damper Assembly LND42 420...

Page 128: ...Parts Lists and Drawings 9 28 750 204 Profire D LND 9 4 13 Drawer Assembly D42 63...

Page 130: ...Parts Lists and Drawings 9 30 750 204 Profire D LND 9 4 14 Drawer Assembly D84 145...

Page 132: ...Parts Lists and Drawings 9 32 750 204 Profire D LND 9 4 15 Drawer Assembly D175 336...

Page 134: ...Parts Lists and Drawings 9 34 750 204 Profire D LND 9 4 16 Drawer Assembly D378 420...

Page 136: ...Parts Lists and Drawings 9 36 750 204 Profire D LND 9 4 17 Firing Head Assembly D42 420...

Page 139: ...750 204 Profire D LND 9 39 9 4 Parts Lists and Drawings 9 4 19 Oil Heater D42 420...

Page 146: ...Parts Lists and Drawings 9 46 750 204 Profire D LND 9 4 22 Oil Metering Assembly D378 420...

Page 156: ...750 204 Profire D LND...

Page 159: ......

Page 160: ......