Maintenance

5-6

750-437

Q Series Full Modulation

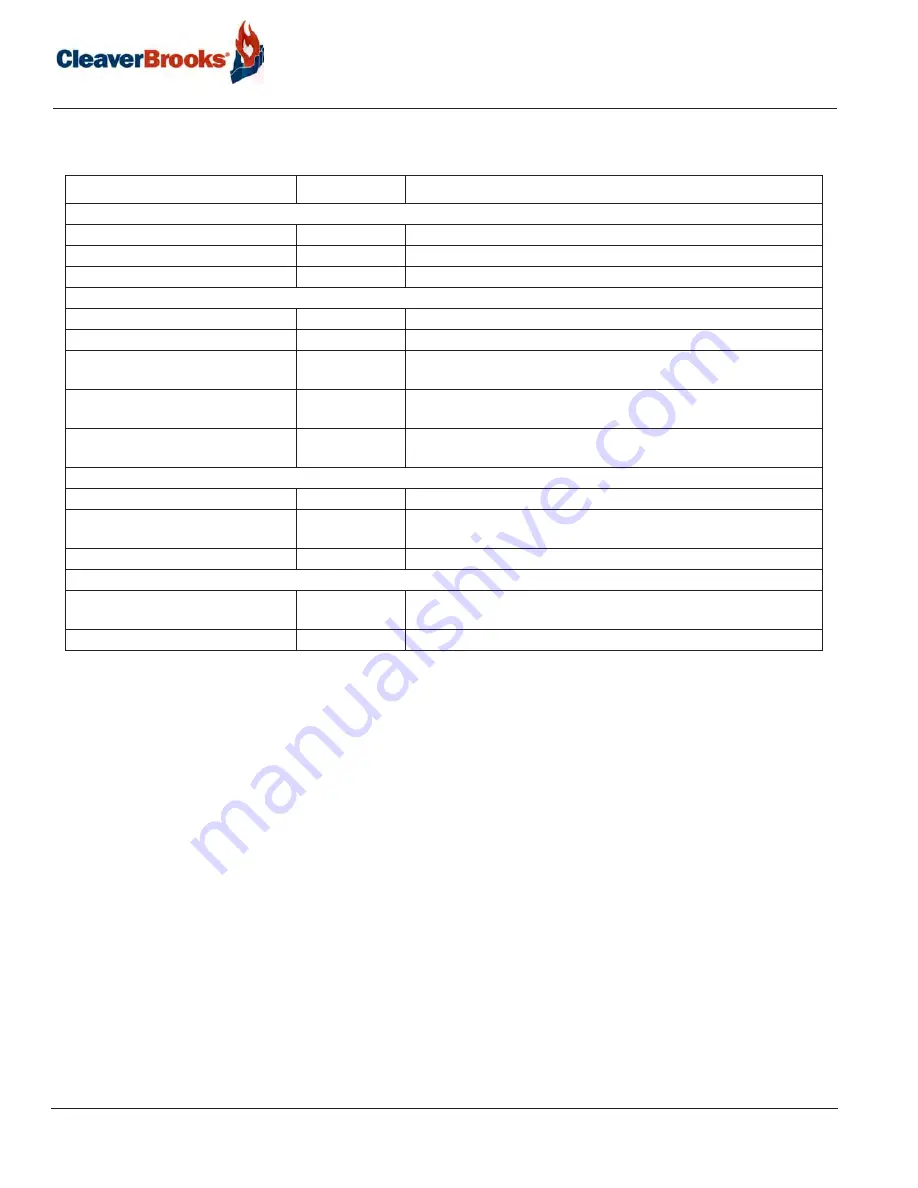

5.12 — Recommended Maintenance Schedule

TABLE 5-1.

Maintenance Schedule

Item

Service By

Remarks

DAILY

Gauges, Monitors, Indicators

Operator

Make visual inspection and record readings in log.

Instrument & Equipment Settings

Operator

Make visual check against recommended specifications.

Low Water, Fuel Cutoff & Alarms

Operator

Refer to instructions.

WEEKLY

Firing Rate Control

Operator

Verify factory settings.

Igniter

Operator

Make visual inspection. Check flame signal strength.

Main Fuel Valves

Operator

Open limit switch. Make audible and visual check. Check valve

position indicators, and check fuel meters.

Flame Failure Controls

Operator

Close manual fuel supply valve(s). Check safety shutdown

timing. Record in log.

Flame Signal Strength Controls

Operator

Read and log the flame signal for main flame (Parameter 954).

Notify Service if readings are very high, very low, or fluctuating.

MONTHLY

Low Fan Pressure Interlock

Operator

Manually adjust until switch opens.

High & Low Gas Pressure

Interlocks

Operator

Refer to instructions. Manually adjust until switch opens.

Scanner

Operator

Check, inspect, and clean for soot buildup.

ANNUALLY

Combustion Test

Service Tech

Perform a complete combustion test. Adjust burner if

necessary. Read and log data.

Operating Controls

Service Tech

Refer to instructions.

Summary of Contents for ProFire Q Series

Page 2: ......

Page 18: ...Introduction 1 8 750 437 Q Series Full Modulation...

Page 28: ...Installation 2 10 750 437 Q Series Full Modulation...

Page 50: ...Operation 3 22 750 437 Q Series Full Modulation...

Page 82: ...Troubleshooting 6 24 750 437 Q Series Full Modulation...

Page 87: ......

Page 88: ......