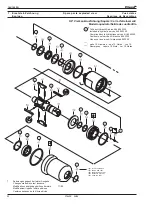

10

P1643E 04/06

140/160PH

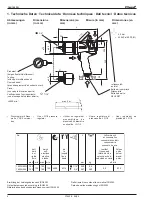

6.6 Oil Filling

After the filling the pulse unit must be tightened to the

required torque.

1. Connect the pulse unit to the quick disconnect coupling using the

adapter

<A2>

.

2. Close the shut-off valve.

3. Connect air supply of approx. 5 bar.

4. Slowly open the shut-off valve fully, until the vacuum pressure

gauge shows approx. 1 mbar (-1 bar).

5. Wait for approx. 2 minutes until the number of vacuum bubbles has

decreased substantially.

6. Slowly close the shut-off valve. The pressure gauge indicates

atmospheric pressure again. Missing oil is pressed into the pulse

unit.

7. If necessary, repeat the steps 4. to 6. until no more bubbles come

out.

8. Disconnect the pulse unit, remove the adapter and add a few drops

of oil with syringe

<B>

.

-

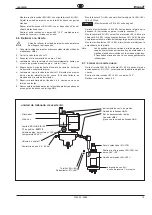

Install the ball <57>/<84> and tighten the set bolt <58>/<85>

(2,9 ±0,3 Nm).

Caution!

Caution!

The bearing ring <73>/<118> must not turn along!

-

Tighten threaded ring by the required torque (8. Assembly

instructions, fig. 7)

-

Fit ball bearing <60>/<87> with the circlip <59>/ <86> into the

housing <62>/<89>. Insert the O-ring <61>/<88>. Push fully over

the long shaft end of the hydraulic rotor.

-

Fit ring retaining ring <35>/<90>. Screw the whole component

onto the pistol grip.

Remarks:

Small bubbles appearing at high vacuum pressure in the wetting

layer between the oil and the material are not indicating leakage of

the pulse unit. The filling result will not be affected thereby.

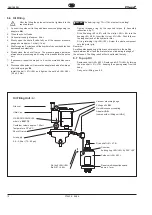

6.7 Top up Oil

-

Remove set bolt <58>/<85>. Remove ball <57>/<84> by turning

the drive shaft <51>/<78>, keeping the opening away from the

body.

-

Carry out oil filling, see 6.6.

Set bolt <58>/<85>

Ball <57>/<84>

Vacuum pressure gauge

Filling unit

<A1>

Quick disconnect coupling

Adapter

<A2>

(comes with oil filling unit

<A>

)

Unscrew

bearing ring <55>/<82> by 360° +90°

Pulse unit <36>/<63>

Reserve-oil inspection space

approx. 1 mm

Drive shaft <51>/<78>

Silencer

Ultra-Vac

Oil: ESSO-UNIVIS J26

order no.

925715

Container volume approx. 150ml

Temperature 20°±5°C

Shut-off valve

Air supply

4,5 - 5,5 bar (70 - 80 psi)

Oil Filling Unit

<A>

Summary of Contents for 140PH

Page 31: ......