Page 12

PL12-1014EN

10/16/2014

Cleco

®

General Information

8.1

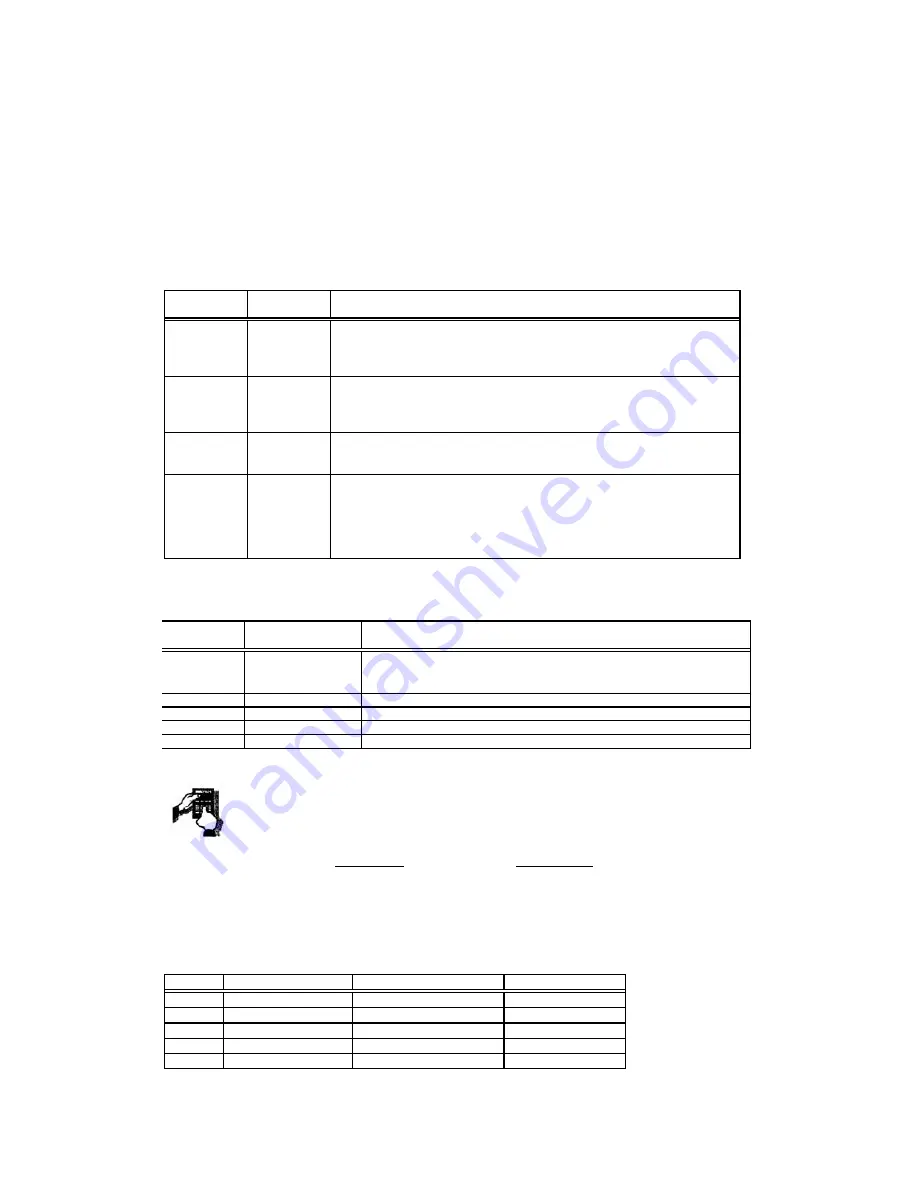

Service schedule

Only qualified and trained personnel are permitted to perform maintenance on these tools.

Regular maintenance reduces operating faults, repair costs and downtime. In addition to the following

service schedule, implement a safetu related maintenance program that takes the local regulations for

repair and maintenance for all operating phases of the tool into account.

This maintenance schedule uses values that are valid for most applications. For a specific maintenance

interval, refer to 8.1.1 Calculating a customer-specific maintenance plan.

8.1.1

Calculating a customer specific maintenance plan

A service interval W(1, 2, 3) depends on the following factors:

8.2

Lubricants

For proper function and long service life, use of the correct grease is essential.

Maintenance

Interval

Rundowns

Daily

Daily

Ú

Ú

Ú

Ú

Visual inspection of air supply hose and connections

Inspect airline filter, regulator and lubricator for proper operation

Check the tool excessive vibration or unusual noises

Visual inspection of all external components of the tool

W1

100,000

Ú

Ú

Ú

Ú

Inspect the air hose for damage or wear

inspect the square drive output spindle for damage or wear

Inspect the air inlet adapter for a secure fit

Check the maximum free speed

W2

500,000

Ú

Ú

Ú

Check individual parts and replace if necessary

Replace O-rings and seals

Clean bronze mufflers

W3

1,000,000

Ú

Ú

Ú

Ú

Ú

Ú

Check individual parts and replace if necessary

Throttle valve

Motor

Gearing

Clutch (19RAA)

Angle attachment

Designation

Part No.

Packaged

Designation

Vendor

540450

18 oz. (0.51 kg)

Black Pearl EP-NLGI-0

Chevron

540395

2 oz. (0.06 kg)

Magnalube-G

Carleton-Stuart Corp.

513156

16 oz. (0.45 kg)

Magnalube-G

Carleton-Stuart Corp.

541444

2 oz. (0.06 kg)

Rheolube 363AX-1

Nye Lubricants, Inc.

541445

16 oz. (0.45 kg)

Rheolube 363AX-1

Nye Lubricants, Inc.

Example for service interval W2:

After 500,000 rundowns (V),

a specific rundown time of 1.8 seconds (T1)

with an actual fastening time of 3 seconds (soft joint) and

3 completed shifts per day and 750 rundowns per shift.

V x T1

500000 x 1.8

T2 x S x VS

3 x 3 x 750

You will need to perform the maintenance indicated as W2 after an operating time of 133 days.)

W (1, 2, 3) =

W2 =

= 133 (days)

Factor

Value assumed in

"Service Schedule"

Description

V

V1 = 100,000

V2 - 500,000

V3 = 1,000,000

Number of rundowns after a maintenance measure is prescribed by Apex

Tool Group.

T1

1.8 seconds

Specific rundown time, measured in life and endurance tests.

T2

2 seconds

Actual rundown time, depending on the hardness of the joint.

S

1; 2; 3

Number of shifts per day.

VS

750

Number of rundowns per shift.

T2, S and VS are variable factors and can differ depending on the specific application.