Page 17

PL12EN-48ET

02/15/2013

Cleco

®

Troubleshooting

7

Troubleshooting

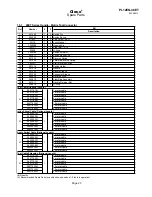

Malfunction

Possible causes

Remedy

Start switch faulty

Ú

Replace start switch

No speed (RPM) programmed

Ú

Program a speed for all active stages

Controller is waiting for a Tool Enable

Ú

Make the Tool Enable connection or disable Tool

Enable if not required

Faulty cable

Ú

Replace or repair cable

Bent pins in cable or tool

Ú

Straighten pins or replace faulty connector

No speed programmed for Reverse

Ú

Enter a speed (RPM) for Reverse

Faulty reverse switch

Ú

Replace Start/Reverse switch assembly

Faulty cable

Ú

Replace or repair cable

Bent pins in cable or tool

Ú

Straighten pins or replace faulty connector

Operator is releasing the start switch

before the controller stops the tool

Ú

Verify that the operator is keeping the start

switch depressed through the entire rundown

Rundown time exceeds the default

time value of 10 seconds

Ú

Increase the rundown timer to exceed the

rundown time required

Tool won't change speeds

Speeds are the same in all applicale

stages

Ú

Verify that all speeds and shift points are correct

in the stages that are being used.

All the lights on the tool

begin flashing when the

reverse collar/switch is put

in reverse

This is a normal function as set by

the default parameters. If the lights

are not flashing when the tool is in

reverse the "Blinking Lights in

Reverse" check box is not selected.

Ú

Check selections in the ADVANCED menu, Tool

Settings tab.

The tool tranducer is not returning to

a zero torque condition

Ú

Transducer has been over-stressed and needs

replacement

Faulty wiring in tool or cable

Ú

Check tool with different cable to see if the

condition remains. Transducer offset and full

scale voltages can be seen in the

DIAGNOSTICS menu.

Tool has not been accepted in the

TOOL SETUP screen

Ú

Verify that the tool has been accepted in the

TOOL SETUP screen. Before accepting the tool,

the message "Needs User Acceptance" should

appear in the tool overview screen. Verify that

the correct tool is highlighted when going to Tool

Settings to accept the tool.

Faulty cable is preventing the tool

from being "seen" by the controller

Ú

Replace or repair cable

Torque calibration factor in Tool

Settings in the TOOL SETUP menu

needs to be adjusted

Ú

Adjust torque calibration factor using the formula

below:

New Cal Facor = (External Reading/Tool

Reading) x Existing Torque Calibration Facor

Custom head has been added to the

tool and the tool needs updated tool

memory information

Ú

Tool memory must be programmed to

accommodate new attachment

Tool cable will not fit in tool

handle

Wrong cable. Tools used with Global

Controller utilize an Air-lb connector,

which has a smaller ID housing in the

tool than previous Matrix style

connector housings.

Ú

Utilize the correct cable for the tool being used.

Torque reported by the

controller doesn't match the

torque reported by an

external transducer

Tool does not start

Tool runs forward but not

Reverse

Warning message in the

RUN screen reports

"Transducer Offset Error"

"Tool Not Connected"

message appears in the

RUN screen

Tool shuts off prematurely