Page 19

PL12EN-48ET

02/15/2013

Cleco

®

Maintenance

8.1.1

Calculating a customer specific maintenance plan

A service interval W(1, 2, 3) depends on the following factors:

8.2

Lubricants

For proper function and long service life, use of the correct grease is essential.

Grease lubricants recommended for this tool.

Example for service interval W2:

After 500,000 rundowns (V),

a specific rundown time of 1.8 seconds (T1)

with an actual fastening time of 3 seconds (soft joint) and

3 completed shifts per day and 750 rundowns per shift.

V x T1

500000 x 1.8

T2 x S x VS

3 x 3 x 750

You will need to perform the maintenance indicated as W2 after an operating time of 133 days.)

W (1, 2, 3) =

W2 =

= 133 (days)

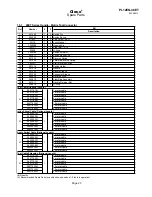

Factor

Value assumed in

"Service Schedule"

Description

V

V1 = 100,000

V2 - 500,000

V3 = 1,000,000

Number of rundowns after a maintenance measure is prescribed by Apex

Tool Group.

T1

1.8 seconds

Specific rundown time, measured in life and endurance tests.

T2

2 seconds

Actual rundown time, depending on the hardness of the joint.

S

1; 2; 3

Number of shifts per day.

VS

750

Number of rundowns per shift.

T2, S and VS are variable factors and can differ depending on the specific application.

Part No.

Packaged

Designation

Vendor

544076

2 oz. (0.06 kg)

Molytex EP2

Texaco

544077

16 oz. (0.45 kg)

Molytex EP2

Texaco

540395

2 oz. (0.06 kg)

Magnalube-G

Carleton-Stuart Corp.

513156

16 oz. (0.45 kg)

Magnalube-G

Carleton-Stuart Corp.

541444

2 oz. (0.06 kg)

Rheolube 363AX-1

Nye Lubricants, Inc.

541445

16 oz. (0.45 kg)

Rheolube 363AX-1

Nye Lubricants, Inc.