4

OPERATING INSTRUCTIONS

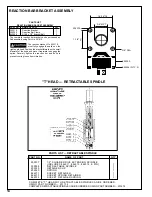

LUBRICATION

An automatic in-line filter-lubricator-regulator is recom-

mended as it increases tool life and keeps the tool in

sustained operation. The in-line lubricator should be regu-

larly checked and filled with a good grade of 10W machine

oil. Proper adjustment of the in-line lubricator is performed

by placing a sheet of paper next to the exhaust ports and

holding the throttle open for approximately 30 seconds. The

lubricator is properly set when a very light stain of oil collects

on the paper. Excessive amounts of oil should be avoided.

Application of the tool should govern how frequently it is

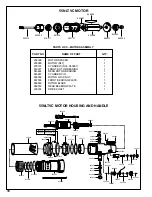

greased. It is recommended that the idler gears and right

angle gears receive a generous amount of NLGI 2-EP

grease through the grease fittings after 40 hours of opera-

tion.

STORAGE

In the event that it becomes necessary to store the tool for

an extended period of time, it should receive a generous

amount of lubrication at that time and again when returned

to service. The tool should be stored in a clean and dry

environment. This inhibits corrosion of the precision inter-

nal components and bearings.

FOR YOUR SAFETY AND THE SAFETY OF OTHERS, READ AND UNDERSTAND THE SAFETY

RECOMMENDATIONS ON PAGES 2 & 3 BEFORE OPERATING A NUTRUNNER.

TORQUE ADJUSTMENT

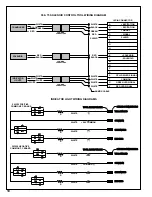

The 55NLTVC nutrunner is designed to develop maximum

rated torque at 90 psig. The torque setting is achieved by

entering a number within the tool's torque range into the

torque control monitor. See catalog for torque range of tool.

The torque setting entered into the torque control monitor

must not exceed maximum torque range of tool or the

automatic shut-off device will not function and the tool will

operate as a stall tool. Operator should be prepared to resist

torque reaction until throttle is released.

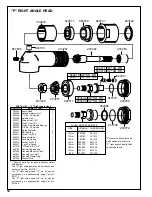

THROTTLE POSITION

The throttle lever may be repositioned to accommodate

proper location for task and to avoid entrapment. Reposi-

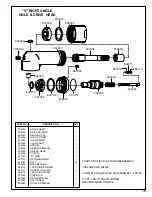

tioning of the angle head is done by loosening housing lock

nut No. 867521, and lifting the angle head until the spline on

the angle head clears the gear case and can be rotated to

the position desired. Lower the angle head back into place

and tighten housing lock nut.

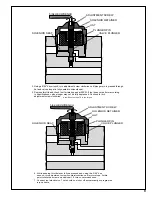

AIR SUPPLY

For maximum performance, use a 1/2" I.D. air hose no

longer than 8' in length. If additional length is required, a

5/8" or larger hose should be connected to the 1/2" hose.

Being careful to avoid endangering adjacent personnel or

yourself, the air hose should be cleared of accumulated dirt

and moisture, then one (1) teaspoonful of 10W machine oil

should be poured into the tool's air inlet before connecting

the hose to the tool.

Summary of Contents for 55NLTVC Series

Page 21: ...21...

Page 22: ...22 NOTES...

Page 23: ...23 NOTES...

Page 24: ...24 670 Industrial Drive Lexington SC 29072 Phone 803 359 1200 Fax 803 359 2013...