7

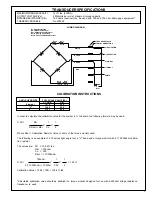

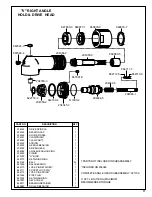

TRANSDUCER SPECIFICATIONS

MAXIMUM TORQUE CAPACITY

147 ft. lbs. (200 Nm)

OUTPUT VOLTAGE (Vo)

2 Millivolts per volt at maximum torque capacity

BRIDGE RESISTANCE (Rbr)

700 ohms (nominal) can be used with 350 and 700 ohm strain gage equipment*

TRANSDUCER CABLE

No. 203450

CALIBRATION INSTRUCTIONS

ANGLE HEAD SIZE FULL SCALE VALUE (FS)

FT. LBS. Nm

Straight

147.5

200

"V"

196.2

266

"X"

312.7

424

In order to calculate the calibration value for the system in % full scale, the following formula may be used:

% FS = Rbr

1

1

------------------ X ----- X -----

2(Rcal) + Rbr Vo

2

Where Rcal = Calibration Resistor Value in ohms of the torque monitor used.

The following is an example of a 75 series right angle tool, a "V" head and a torque monitor with a 110,000ohm calibra-

tion resistor.

The values are: FS = 196.2 ft. lbs.

Rbr = 700ohm

Vo = .002

Rcal = 110,000ohm

700ohm

1

1

% FS = --------------------------- X ------ X ----- = 79.3%

2(110,000ohm) + 700ohm .002

2

Calibration Value = 196.2 (.793) = 155.6 ft. lbs.

*Calculated calibration value should be doubled if a torque monitor designed for use with a 350ohm bridge resistance

transducer is used.

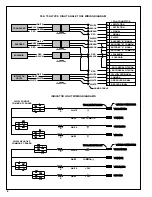

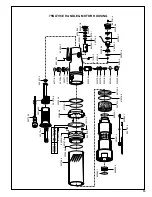

A

A

B

B

C

C

D

D

BLACK

GREEN

RED

WHITE

TOOL RECEPTACLE

CABLE CONNECTORS

R

WIRING DIAGRAM

E

E

F

F

(+) SIGNAL

(-) SIGNAL

SHIELD

(+) EXCITATION

(-) EXCITATION

Ro/2

Rm/2

R

R

R

t

C

t

C

Ro/2

Rm/2

Rcal

R= Gage Resistance

Rm= Modulus Resistor

Ro= Output Scaling Resistor

Rm & Ro may be omitted

Rcal= Shunt Calibration Resistor

Summary of Contents for 75NLTVCE Series

Page 18: ...18...

Page 19: ...19 NOTES...

Page 20: ...20 670 Industrial Drive Lexington SC 29072 Phone 803 359 1200 Fax 803 359 2013...