Page 5

823108EN

12/31/2015

Cleco

®

Service

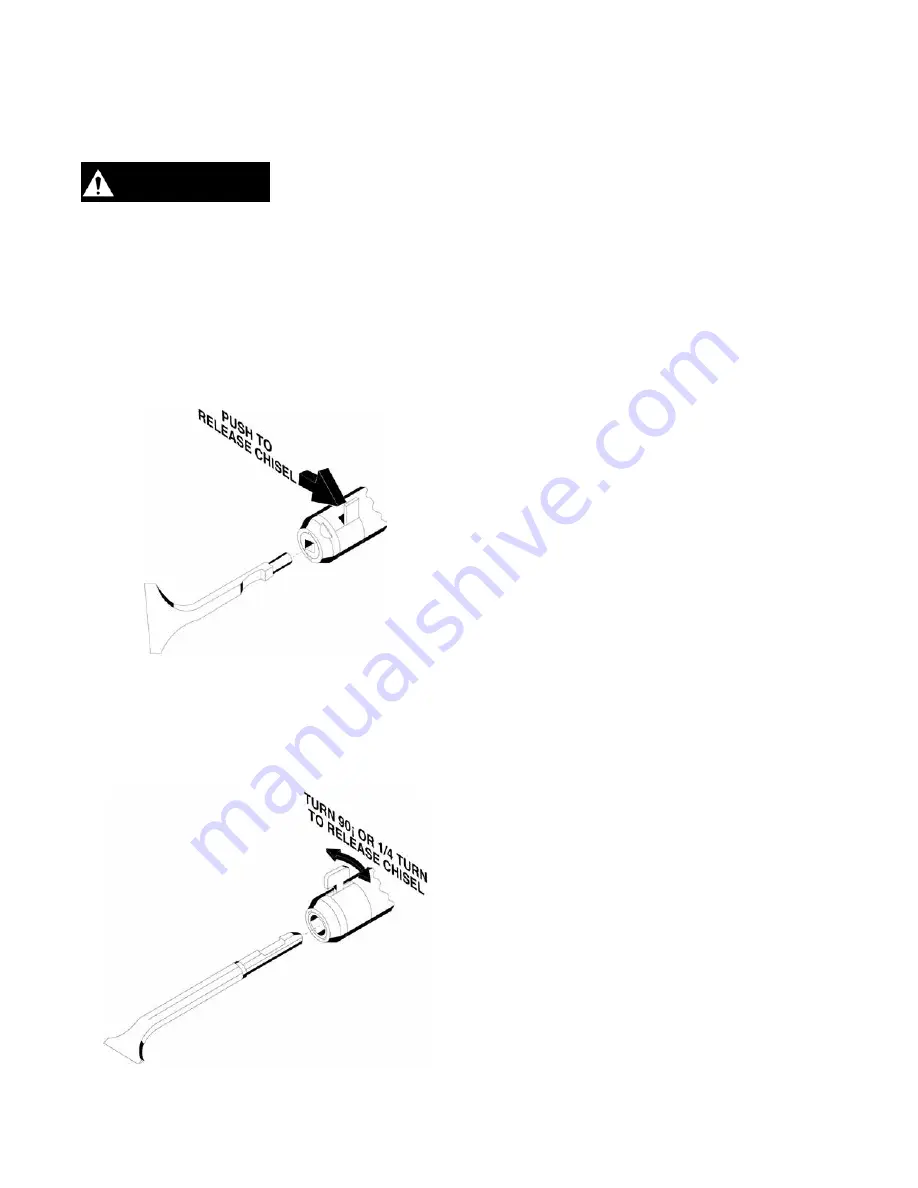

Chisel Removal:

Turn off the air supply and disconnect the air hose from

the tool before removing any chisel or implement.

Use only notched B1-C approved safety retainer chisels

with B1-C scalers and notched BR-C approved safety

retainer chisels with BR-C scalers. Refer to Illustration

“F” for a list of approved chisels.

B1-C Series Models:

Push the tang on the driver retainer (832956), away from

the barrel to remove the chisel (see illustration below).

BR-C Series Models:

Rotate the driver retainer (869314) 90° or 1/4 turn in

either direction to remove the chisel (see illustration

below). Rotate the driver retainer back to its in-line

position with the barrel after chisel replacement.

Disassembly and Assembly:

Use Apex Tool Group, LLC or Apex Tool Group GmbH

& Co. OHG’s lightweight air tool oil 500021 (available

in quantities shown in the following chart) or an SAE-5

lightweight spindle oil.

B1-C-BV Pistol Grip Models:

Should if be necessary to replace the throttle valve

casing (832054), thread a 7/16-20 bolt into the casing

and using a suitable puller, remove it from the handle.

Refer to Illustration “C”.

Inspect Parts:

Clean and inspect all parts for excessive wear or

damage and replace as necessary with genuine Cleco

replacement parts. Replace all o-rings and seals

whenever the tool is disassembled.

Common issues to look for:

• Worn out retainer buffer (833527), used in the B1

series tools. This can be caused by operating the

tool without any resistance against the chisel.

• Excessive wear in the tool nose.

• Worn or scored plunger (832373 or 832944) usually

caused by foreign particles entering the tool.

• Worn or scored bore in the barrel sleeve (832700 or

832943) caused by foreign particles entering the tool.

Handle Assembly:

If the handle does not position as desired in relationship

to the chisel position, one or more handle positioning

shims (832947) may be placed between the valve

assembly and the handle. Refer to Illustrations “A”, “B”,

and “C”.

Use one shim for about every 30° desired. Always tighten

the handle into the barrel until the valve assembly is tight

against the barrel sleeve and then tighten the handle

lock ring (832882).

After the tool is assembled, pour a few drops of 10W

machine oil into the inlet bushing to ensure immediate

lubrication of the tool components.

B1-C-PT Series Throttle Valve Adjustment:

To adjust the throttle valve for the desired power, loosen

the throttle valve casing lock nut (843645) and screw the

controlling valve handle (832610) to a position so that

the desired blow is delivered when the handle is fully

compressed. Tighten the throttle valve casing lock nut to

secure the controlling valve handle in position. Refer to

Illustration “A”.

WARNING