14

P2055MA | 2019-09

Apex Tool Group

EN

6

Ambient conditions

Industrial environment EMC limit class value A, DIN EN 55 0081-2.

7

Noise

See P3223H Declaration of Incorporation for Incomplete Machines.

8

Maintenance

Regular maintenance reduces operating faults, repair costs and downtime. Implement a safety-related

maintenance program that takes the local regulations for repair and maintenance for all operating phases of

the tool into account.

Only trained personnel are permitted to perform maintenance. See P2090WA Service Manual.

9

Disposal

Components of the Spindle pose risks to the health and the environment.

The Spindle contains components that can be reused as well as components that require special disposal.

Separate the components and dispose of them by segregating them clearly.

Catch auxiliary materials (oils, greases) when drained and dispose of them properly.

Separate the components of the packing and dispose of them by segregating them clearly.

Follow the locally applicable regulations.

Enclosure type

according to

DIN 40050

Ambient tem-

perature

Relative

humidity

Working height

Storage tem-

perature

IP40

32 to 113 °F

a

(0…45 °C)

a Observe Derating, see System Handbook

0 to 90 % no con-

densation

Up to 3000 m

1)

above sea level

77 to 158 °F

(25…70 °C)

Observe generally valid disposal guidelines such as, in Germany, the Electrical and

Electronic Equipment Act (ElektroG):

Hand in the Spindle at your company collection point or return to

Sales & Service

Centers

.

Summary of Contents for BB P2055MA

Page 4: ...4 P2055MA 2019 09 Apex Tool Group EN ...

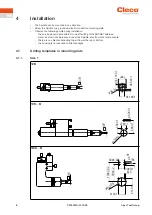

Page 9: ...Apex Tool Group P2055MA 2019 09 9 EN 4 1 2 Size 2 2ZB 2VK B 2WK B 0 ...

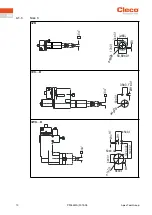

Page 10: ...10 P2055MA 2019 09 Apex Tool Group EN 4 1 3 Size 3 3ZB 3VK B 3WK B 0 ...

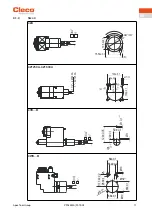

Page 11: ...Apex Tool Group P2055MA 2019 09 11 EN 4 1 4 Size 4 4ZA 4Z1250A 4Z1600A 4VK B 4WK B 0 ...

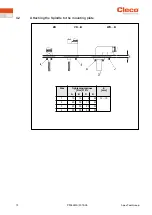

Page 15: ......