1891f-enu_Ersatzteile.fm, 25.04.2014

P1891E/EN 2014-02

59

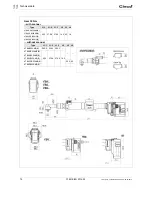

Spare parts

10

10

Spare parts

Always use only original

Cleco

spare parts. Failure to comply with this instruction can result in decreased

performance and an increased need for servicing. Installing spare parts from other manufacturers will void

all manufacturer's warranties. Information,

but no warning of hazards.