Page 7

TM12-1109-LG1

08/25/2017

EN

General Safety Instructions: Controller

→ Turn off the controller before connecting power or

tool cables, during changeover, cleaning, and taking

out of operation.

→ Do not modify the controller, protective devices, or

accessories without prior written authorization from

Apex Tool Group LLC.

→ Do not open the controller or the components of

the controller. Any interference can cause an error

resulting in serious injury from electrical shock.

→ Opening the controller will void the manufacturer’s

warranty.

→ Send the controller for service and maintenance to

an authorized Cleco Sales and Service Center.

1 Designated use

This product is part of the Cleco tightening system and

is intended exclusively for industrial use in fastening

processes.

Use the controller only under the following conditions:

• In conjunction with the components listed in the EC

Declaration of Conformity P3268C.

• With the permissible supply voltage.

• In EMC Limit Class A (electromagnetic immunity for

industrial areas). For the currently observed EMC

standards, see the EC Declaration of Conformity.

Do not use the controller:

• In potentially explosive areas.

• In damp areas or outdoors.

2 Ambient conditions

→ Keep the controller away from heat, fire, risk of

explosion, and moisture.

3 Power supply

→ Operate only on a grounded power supply (TN

system). Operation on an IT system is not permitted.

4 Installation

Risk of crushing. The controller could fall causing

personnel injury.

→ Use suitable lifting equipment during installation.

→ Observe facility safety requirements during

installation of the controller.

→ Use approved mounting hardware for the controller:

4xM6 properly tightened to prevent loosening (see

hardware description P2300HW).

→ Install all tool and power cables so that they are not

damaged and do not present a trip hazard.

→ Do not exceed a total cable length of 45 m (147.6 ft.).

In case of failure, high voltage leakage may occur and

cause injuries as mentioned previously.

→ Use the Cleco recommended regional power cable

when connecting the controller to the power source.

Do not, in any way, modify the Cleco supplied power

cord.

→ Potential charge on assembled products and

conveyance systems needs to be recognized and

managed to prevent operator injury.

→ Before energizing the controller, ensure that all

connections have been properly made (see

Hardware Description P2300HW).

4 Before initial operation

→ Before initial operation perform PE measurement

according to locally applicable regulations (for

example: DGUV Vorschrift 3 in Germany).

→ Observe the safety notes on the controller and the

tool.

→ Check the controller, tool, and cable for any obvious

defects.

→ Replace damaged cables immediately.

5 Operation

→ Immediately shut off the controller in the case of

unusual noise or vibration from the tool. Disconnect

the power supply and have qualified personnel

check the tightening system.

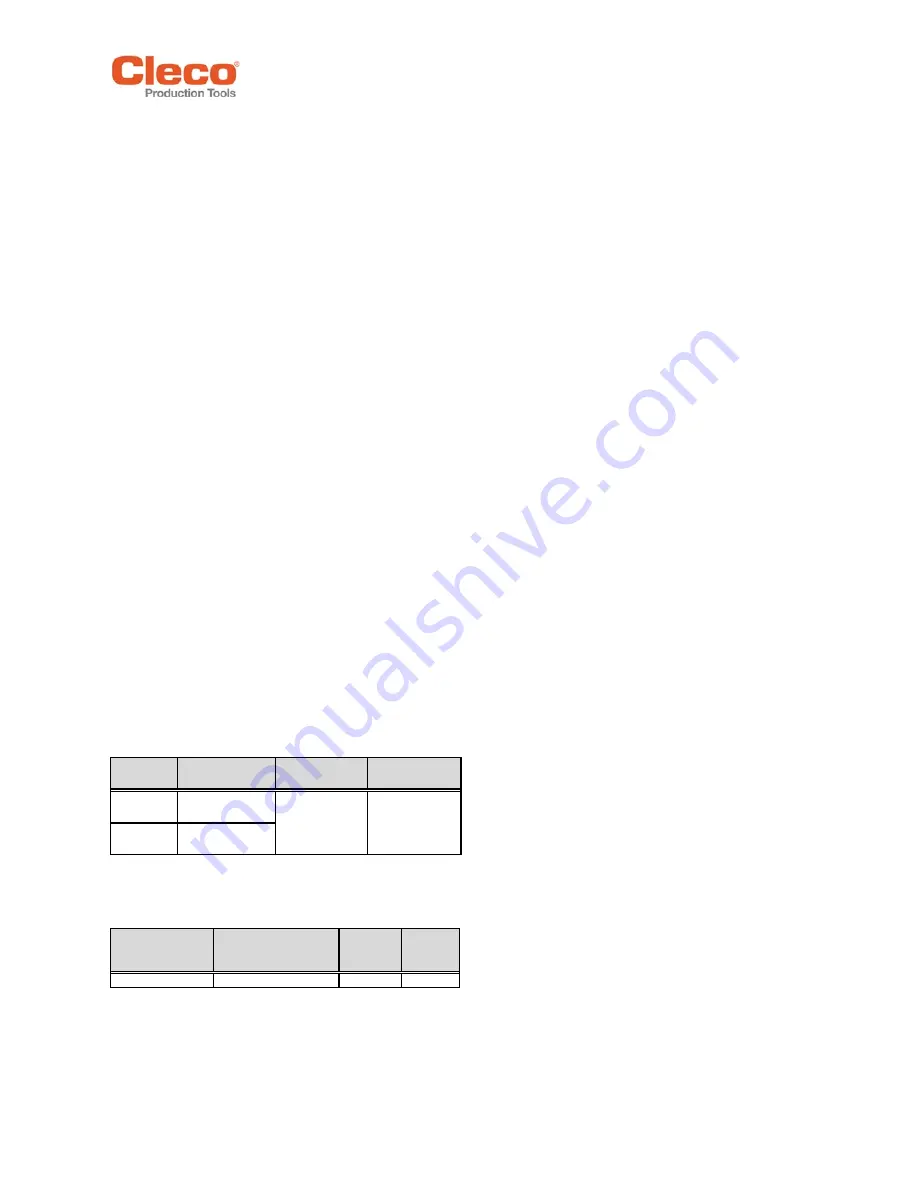

Nutrunner

Control

Input Voltage,

Single Phase

Frequency

Input

Current

16 A max.

mPro400GCD-P

100-240 VAC (± 10%)

50-60 Hz

1-2 A

Function

Temperature

Relative

Humidity

Working

Height

Transport /

Storage

-4°F to +158°F

(-20°C to +70°C)

Ope32°F to +113°F

(0°C to +45°C)

0…90%

non-condensing

up to 9800 ft.

(3000 m)

above sea level