6

onto the front of the cam shaft and hammer assembly.

Rotate the spring clip to accept the anvil pin and then install

the anvil on top of the assembly (be sure the slot in the anvil

lines up with the anvil pin) and drive the anvil down until the

spring clip engages the recess in the anvil.

To install the socket retainer pin, No 867951, in the spline

drive anvil, insert socket retainer spring, No. 867949, and

socket retainer plunger, No. 867950 into the anvil and then

drive the socket retainer pin radially into the plunger.

ANVIL HOUSING

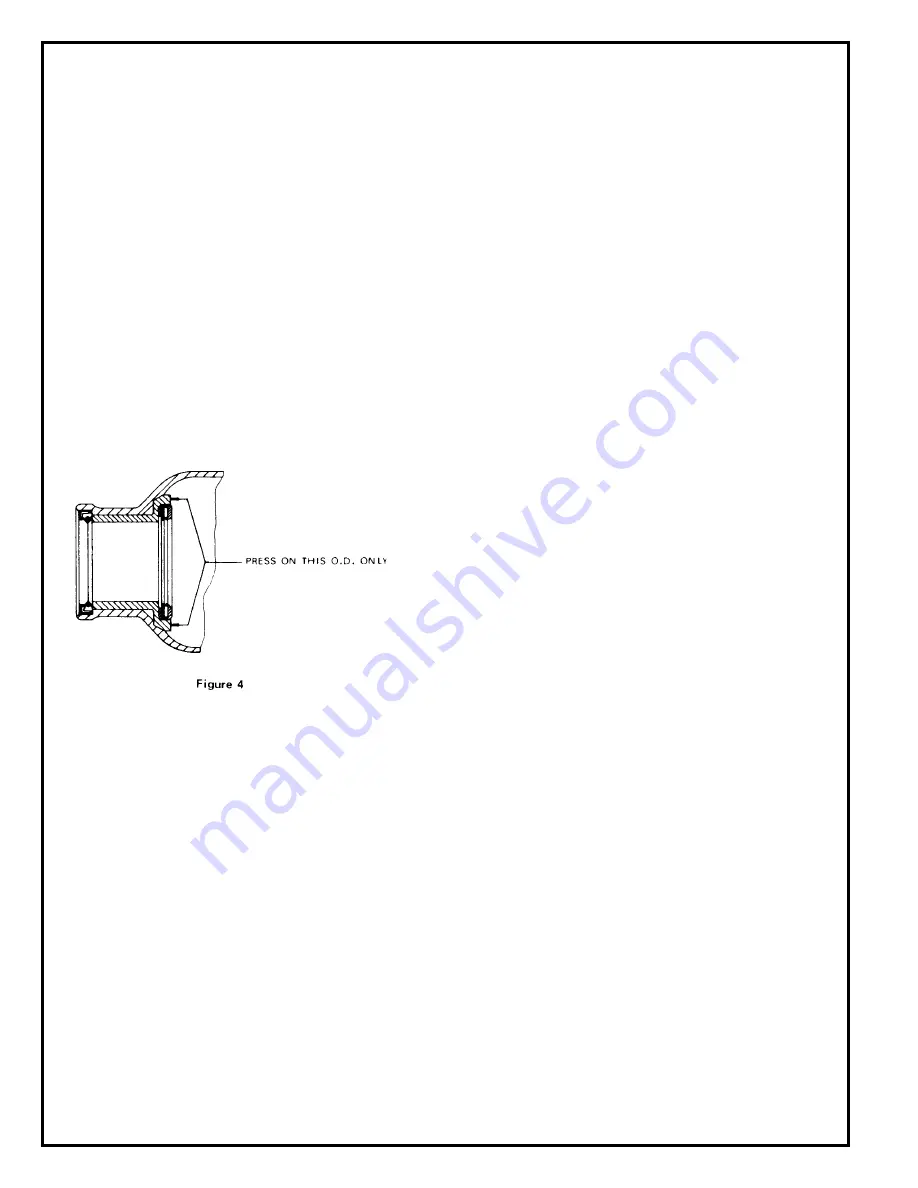

If the anvil housing bushing, No 861602, is replaced, it

should be pressed in as shown in Fig. 4.

When replacing the anvil housing sea), No 867993, the

housing bore should be cleaned with a solvent and then

coated with ''PERMATEX" Aviation Form-A-Gasket No. 3H,

and then be allowed to air dry at least four (4) minutes before

pressing in the seal. Press the seal in with its "lip" toward the

bore of the housing (''Lip'' should not be visible after assem-

bly.)

GENERAL- ALL MODELS

Coat the hammer and rotor splines with 30W oil and insert

the impact mechanism into the front of the rotor Lubricate the

anvil housing seal and bushing with 30W oil and install on the

unit being sure the contour of the anvil housing matches that

of the motor housing The anvil and hammer lugs should be

in line with the recess in the make-up lip located in the anvil

housing. Install the dead handle bracket, No. 867990, on the

left side of the tool and insert the four (4) housing bolts. Tap

the bolts with a hammer until the anvil housing seats against

the motor housing.

Clarnp the tool vertically in a vise and install the gasket Insert

-0--ring, No. 847981, into the reversing valve bore and install

the reversing valve, No. 869008. Apply a thin coat of grease

to the motor clamp seal, No 869001, and place it into the

handle recess.

Put the handle on the tool and install the four (4) nuts, No.

865006. Torque these nuts to 20 ft. lbs. minimum.

Lay the tool on its right side and remove the 30W oil fill plug,

No. 867801. Fill the reservoir with a good grade of 30W oil

up to the level of the fill indicator pin located in the reservoir

(approximately 1 - 1-1/4 fluid Ounces).

Place a couple of teaspoons of 10W machine oil in the air

inlet bushing before attaching the air hose to ensure imme-

diate lubrication of all motor parts.

SAFETY CHECK

All tools should be tested after repair or replacement of parts

to assure that they are functioning properly.

Summary of Contents for W2119 series

Page 7: ...7...

Page 11: ...11 NOTES...