ENGLISH

16

machine forward. The special mechanical drive device uses the friction between brush

and floor to generate a thrust forward; when the mechanical drive lever is released, the

brush motor will therefore switch off and the machine will consequently stop.

If necessary, correct any deviation of the machine and keep it moving in a straight line

via the direction adjustment knob (fig. 6, ref. 10): if the machine tends to veer to the

right, rotate the knob clockwise and vice versa.

•

Versions with electrical drive: to move forwards or backwards, see paragraph 6.3.

In both versions:

•

periodically check that the detergent solution reaches the brushes and refill when

finished; when water in the solution tank is no longer sufficient, the level indicator will

come on (fig. 6, ref. 5): stop and fill the tank;

•

during work check the cleaning quality and adjust the solution flow sent to the brushes

by raising or lowering the lever (fig. 6, ref. 6) as required.

WARNING

Whenever you fill up the solution tank, always empty the recovery tank.

Do not leave the machine stationary with the suction motor on and the solution

cock turned on.

•

If the recovery tank is full, the level indicator will come on (fig. 6, ref 4) and after a few

seconds the suction motor will lock out: stop and empty the tank; to re-start the suction

motor, switch the suction switch off and then on again (fig. 6, ref. 2).

•

Models with battery: if the warning led (fig. 6, ref. 1) starts flashing, it means that the

storage batteries are getting flat. After a few seconds the brushes lock to prevent

excessive unload. Load them.

At the end of work:

•

move the cock lever (fig. 6, ref. 6) to the position “CLOSED”;

•

release the brush/drive lever (fig. 6, ref. 7) placed beneath the handle: the brush/drive

motor switches off and the machine stops;

•

press “0” on the brush switch (fig. 6, ref. 3) to disable the function “Brush”;

•

raising the lever (fig. 6, ref. 8), lift the scrubber from the floor to prevent the drying

blades from warping due to the continuous pressure;

•

let the suction motor run for at least 2 minutes to make sure that it is completely dry;

then press "0" on the suction unit switch (fig. 6, ref. 2) to switch off the suction motor;

•

remove the brushes (or drive discs) to prevent them from warping permanently;

•

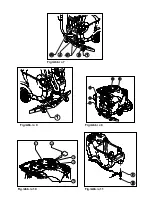

depending on the model, unplug the machine or disconnect the ANDERSON

connectors (fig. 5, ref. 1 and ref. 2);

•

empty and clean the recovery tank.

WARNING

Both lead-acid batteries (set by default) and gel batteries can be installed. If gel

batteries are installed, the dealer must operate the switch on the control panel

electronic board.

6.8

Some useful suggestions for the optimal use of the machine

If the floor presents a particularly resistant type of dirt, it is possible to make the machine

wash and dry it in separate stages.

6.8.1 Pre-washing

•

Open the water cock;

•

set the brush switch to position “1”;

•

lower the head;

•

operate the drive lever to rotate the brushes;

•

ensure that the suction device is off and that the squeegee is raised;