SPECIFICATIONS

70

T12 9009918 (3--2013)

SPECIFICATIONS

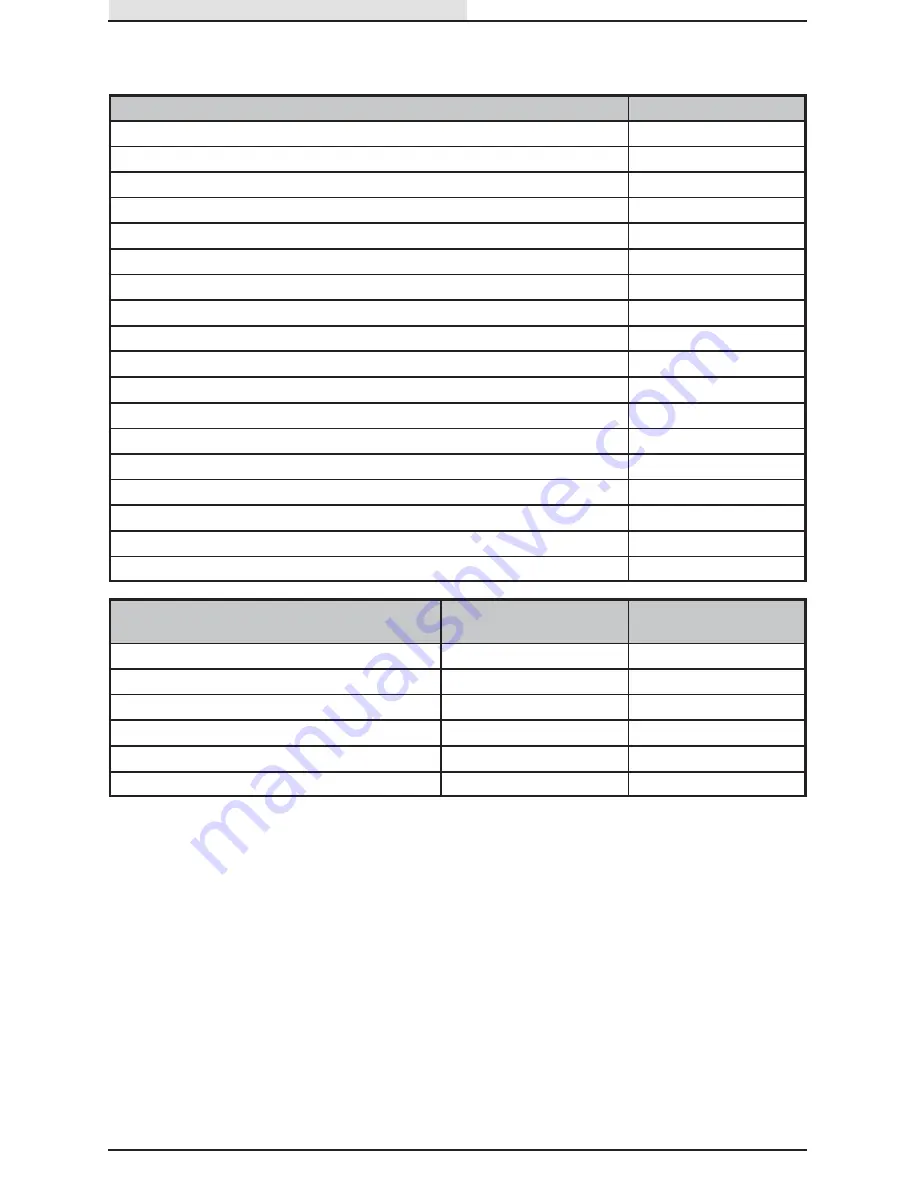

GENERAL MACHINE DIMENSIONS/CAPACITIES

Item

Dimension/capacity

Length

1710 mm (67.25 in)

Width (less squeegee)

945 mm (37.25 in)

Width (with squeegee)

990 mm (39 in)

Width (with side brush)

1065 mm (42 in)

Height

1420 mm (56 in)

Height with overhead guard

2095 mm (82.5 in)

Disk brush diameter for side brush (option)

330 mm (13 in)

Disk brush diameter

405 mm (16 in)

Cylindrical brush diameter

180 mm (7 in)

Cylindrical brush length

780 mm (30.7 in)

Scrubbing path width

810 mm (32 in)

Scrubbing path width (with side brush)

1040 mm (41 in)

Solution tank capacity

132 L (35 gallons)

Recovery tank capacity

166 L (44 gallons)

Demisting chamber

34 L (9 gallons)

Weight (Empty)

468 Kg (1030 lbs)

Weight (with standard 180 Ah batteries)

678 Kg (1494 lbs)

GVWR

1000 Kg (2200 lbs)

Values determined as per EN 60335--2--72

Measure --

Cylindrical scrub head

Measure --

Disk scrub head

Sound pressure level L

pA

63 dB(A)

62 dB(A)

Sound uncertainty K

pA

3.0 dB(A)

3.0 dB(A)

Sound power level L

WA

+ Uncertainty K

WA

86.5 dB(A)

87.5 dB(A)

Vibration -- Hand--arm

1.65 m/s

2

1.65 m/s

2

Vibration -- Whole body

0.32 m/s

2

0.32 m/s

2

Vibration uncertainty K

0.20 m/s

2

0.20 m/s

2