OPERATION

EN

Tennant T2 (07--08)

9

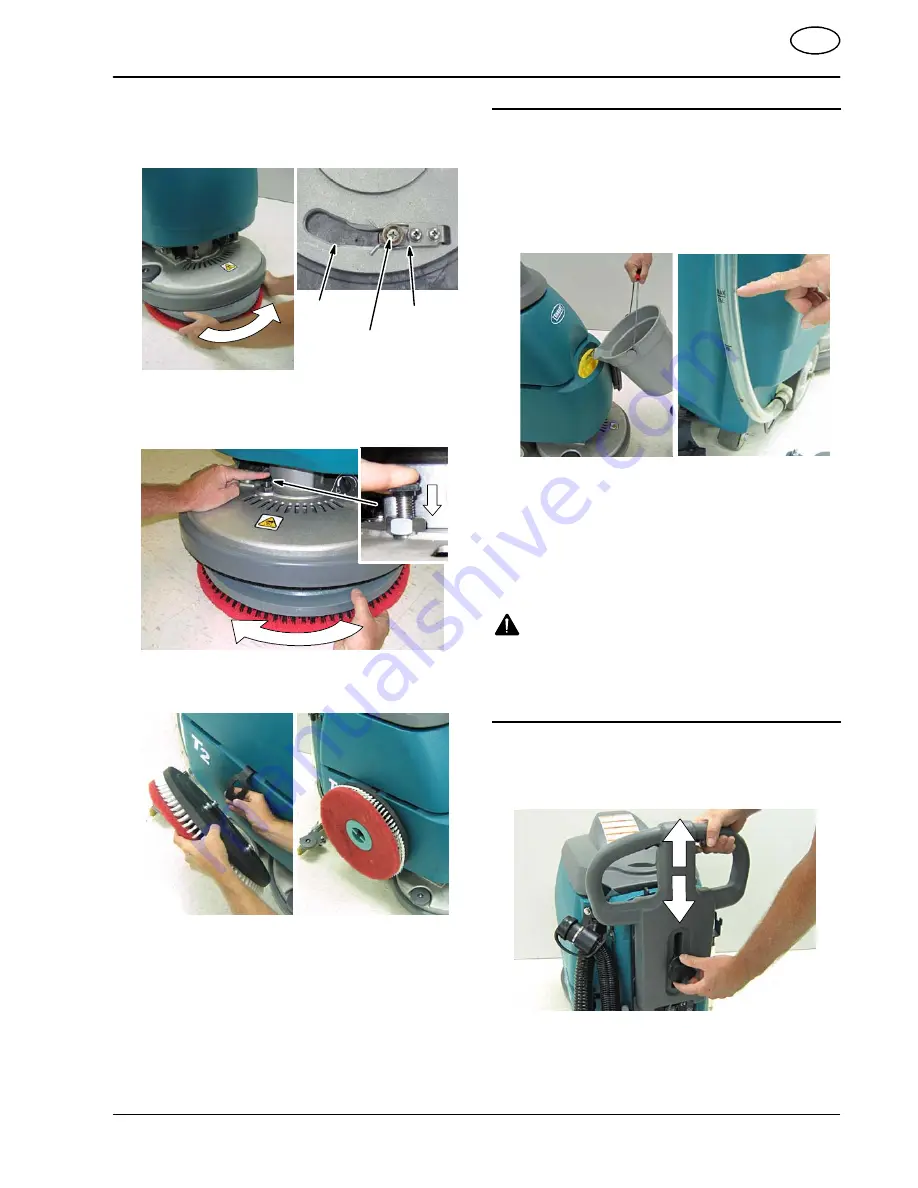

5. Align the pad driver/brush mounting studs with

motor hub slots and give the pad driver/brush a

quick counter--clockwise turn to engage spring clip

(Figure 11).

Spring Clip

Pad Driver/Brush

Mounting Stud

Motor Hub

Slot

FIG. 11

6. To remove the pad driver/ brush, press down on

the motor hub lock pin and turn the pad

driver/brush clockwise (Figure 12).

Lock Pin

FIG. 12

7. When transporting or storing machine, remove the

brush and hang it on the storage strap (Figure 13).

FIG. 13

FILLING SOLUTION TANK

Remove the solution tank cover and fill the tank with 26

liters of water (<60

°

C temperature). Do not fill beyond

the “MAX” level (Figure 14).

NOTE:

When filling the solution tank with a bucket,

make sure that the bucket is clean. Do not use the

same bucket for filling and draining the machine.

FIG. 14

Pour a recommended cleaning detergent into the

solution tank according to mixing instructions on the

bottle.

ATTENTION: Only use recommended cleaning

detergents. Machine damage due to improper

detergent usage will void the manufacturer’s

warranty.

WARNING: Fire or Explosion Hazard.

Never Use Flammable Liquids.

FOR SAFETY: When using machine, follow mixing

and handling instructions on chemical containers.

ADJUSTING CONTROL CONSOLE HEIGHT

Loosen the control console height adjustment knob and

lift or lower the console to a comfortable operating

height. Tighten knob to lock in position (Figure 15).

FIG. 15