OPERATION

EN

Tennant T5 (06--06)

19

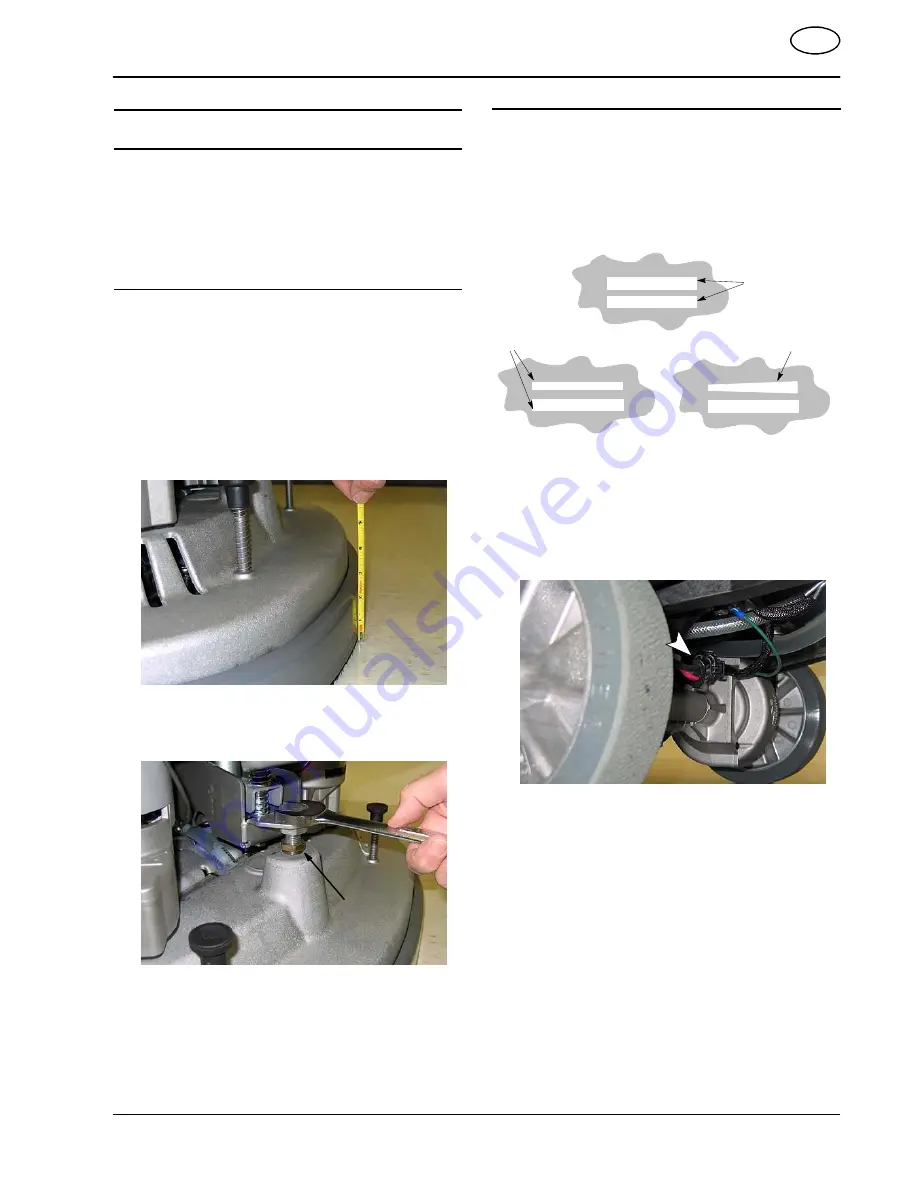

ADJUSTING SCRUB HEAD BRUSHES

To ensure optimum scrubbing performance periodically

check the scrub head for proper adjustment.

FOR SAFETY: Before adjusting scrub head, stop

machine on level surface, remove key and set

parking brake if equipped.

DISK MODEL

Tools required: Measuring device, 27mm wrench and

24mm wrench

1. With brushes installed, lower the scrub head and

apply medium brush pressure.

2. Turn machine off and remove key.

3. From the center front and back of scrub head,

measure the distance from the top edge of scrub

head to the floor (Figure 47).

FIG. 47

4. If scrub head is not level, loosen the lock nut and

turn the scrub head leveling screw to level. Tighten

down the lock nut once head is level (Figure 48).

Lock

Nut

FIG. 48

CYLINDRICAL BRUSH MODEL

After installing a new set of cylindrical brushes check

the brush pattern to ensure proper brush adjustment.

Brushes that are not properly adjusted will result in

premature wear and poor scrubbing performance

(Figure 49).

CORRECT BRUSH PATTERN

INCORRECT BRUSH PATTERNS

Even

Pattern

Tapered

Pattern

Uneven

Pattern

FIG. 49

To Inspect the Brush Pattern:

1. Position the machine on a dry dusty floor or apply a

powdered substance, such as chalk.

2. Disconnect the drive motor wire connector to keep

machine from moving forward (Figure 50).

FIG. 50

3. Lower the scrub head to the floor and apply

maximum brush pressure.

4. Shut off the solution flow.

5. Pull the control handle bail to create a brush

pattern on the floor.

6. Raise the scrub head and pull the machine away.

7. Observe the brush pattern on floor. If the brush

pattern is uneven or tapered, adjustment is

required.

8. Reconnect drive motor wire.