POWER GUN SUCTION BLAST TOOLS

Page 3

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 24189, Rev. C 06/18

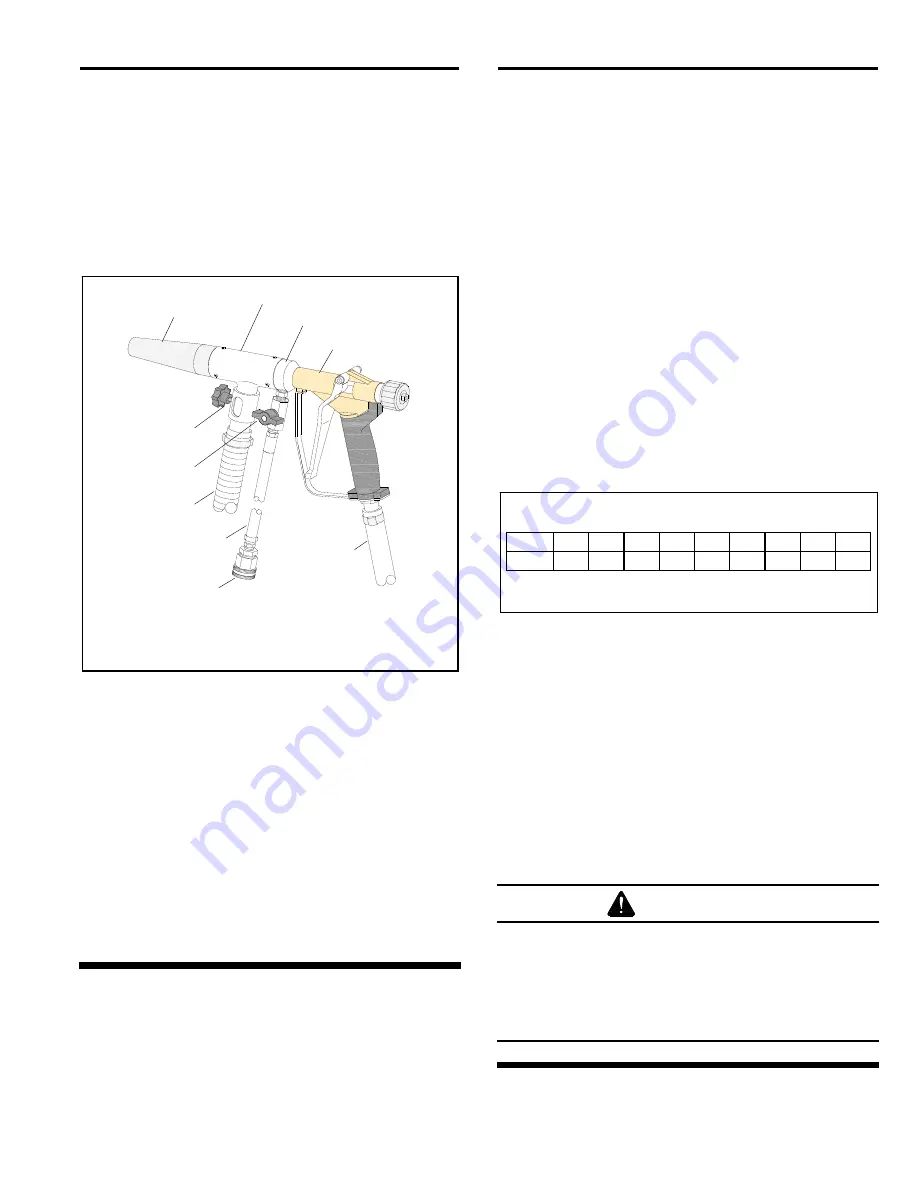

stream is combined with air and abrasive before exiting

the nozzle.

Additional controls on the H2O mixing chamber, allow

the user to control all of the following from the blast gun:

1. Dry blasting with air and abrasive

2. Wet blasting with air, abrasive, and water

3. Wash down with air and water

4. Blow down with air only

Figure

3

1.5.3 Hose

Limitations

1.5.3.1

Material Hose: Standard Power Gun assemblies

come with 16 feet or 30 feet of material hose. The

maximum recommended length is 30 feet, provided

adequate pressure is maintained at the gun and the

nozzle and jet are maintained as noted in Section 6.0.

1.5.3.2

Air Hose: Standard Power Gun assemblies come

with 16 feet or 30 feet of air hose. Longer length of bulk

air hose may be ordered or a 3/4" ID or larger extension

hose may be added, provided adequate pressure is

maintained at the gun. Refer to Section 2.1.

2.0 COMPRESSED-AIR and ABRASIVES

2.1

Compressed Air Requirements

2.1.1

The table in Figure 4 shows approximate air

consumption (cfm) at various pressures (psi) for the

Power Gun alone. Additional air is needed for a

supplied-air respirator, plus other air tools that may be in

use at the same time as the Power Gun. The table

shows air consumption; it does not show the

recommended compressor size. Check with a

compressor supplier for compressor recommendations

based on total compressed-air requirements.

2.1.2

For most applications, the compressor should

be large enough to maintain 80-100 psi under working

conditions. Delicate work may require lower pressure,

and tough applications may require higher pressure.

2.1.3

The air-jet orifice is 1/4" ID and the nozzle orifice

is 1/2" ID.

Air consumption in cfm

PSI 40 50 60 70 80 90

100

120

140

CFM 49 58 67 76 85 94

103

121

138

Figure

4

2.2 Abrasives

2.2.1

Abrasive Size:

The Power Gun utilizes common

abrasives that are 12 mesh and finer. Limited air supply,

low blast pressure, or heavy abrasive may limit abrasive

to smaller sizes.

2.2.2

Use only abrasives specifically manufactured for

blast cleaning and that are compatible with the surface

being blasted. Abrasive produced for other applications

may be inconsistent in size and shape, and contain

particles that could jam the suction gun, and produce an

unsatisfactory finish.

WARNING

All abrasives produce hazardous dust. Obtain a

safety data sheet (SDS) for the blast abrasive

being used and make sure it is available for the

operator to read and understand. Failure to use

appropriate respiratory equipment can result in

injury or death.

H20-Blast Gun Assembly

Air Hose

Material Hose

Nozzle

Mixing Chamber

Gun Assembly

3/4" Female Water

Hose Connection

Water Valve

Water Hose

Water Jacket

Air Induction

Valve